If your brake line threading into your master cylinder is leaking, there’s likely an underlying issue with leak detection. Fortunately, a simple repair can usually resolve the issue quickly and easily.

The brake line is a metal tubing network that distributes fluid from the master cylinder to points near your wheels. It plays an integral role in stopping your car or truck by applying pressure to brake calipers and wheel cylinders.

📢Read also: The S10 Manual Brake Master Cylinder

Brake Line

Your brake line is a rigid metal tubing network that channels brake fluid from the master cylinder down towards your vehicle’s wheels. However, since metal tubing would break if extended all the way to your wheel cylinder or brake caliper, flexible rubber brake hoses are used as part of its final part: this part helps ensure smooth stopping power when applying brake pressure.

Steel brake lines are a popular choice due to their strength and ability to withstand high hydraulic pressures. Unfortunately, over time this steel becomes corroded from moisture and road salt that seeps into your brake line, weakening it and increasing leak potential.

Replace your brake line with corrosion-resistant steel tubing, such as aluminum or stainless steel. Although more expensive to purchase, these materials offer longer service and are ideal for the job at hand.

Master Cylinder

The master cylinder brake is an integral part of your vehicle’s braking system. It converts force from the driver’s foot into hydraulic pressure that then controls slave cylinders situated elsewhere in the system.

The master cylinder consists of a housing, reservoir, piston, rubber cup and return spring. These components slide into an orifice machined in the center of the housing to generate hydraulic pressure.

If you’re not sure how to check for a master cylinder problem, try putting on the brakes and having someone apply pressure to the pedal. If the fluid starts to swirl or bubble, this could be an indication that your master cylinder needs inspection.

A master cylinder is typically designed to last 1 million or more pedal cycles before needing replacement. However, there are factors that can shorten its lifespan; such as being exposed to excessive heat which could cause it to wear out sooner than anticipated.

📢Read also: Brake Master Cylinder Problems on the RX7 Fd

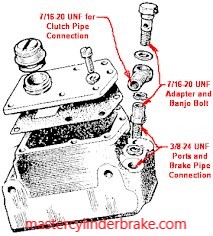

Line Fittings

When it comes to brake systems, many components must be installed correctly for them to function optimally. One such part is brake line fittings which secure the brake hose or line to one another.

Line fittings come in a range of materials, such as steel, stainless steel and brass. Which type you select depends on the application and design of your braking system.

Certain materials are better suited than others when it comes to handling the pressures involved in braking systems. Copper tubing, for instance, is an incredibly strong and malleable material that can bend without breaking.

If a brake line needs to be bent, an experienced tubing bender is necessary. This tool ensures the line has the desired shape without kinking or damage.

Compression Fittings

The braking system is a critical safety element in every vehicle. Therefore, drivers have an obligation to guarantee that the brakes function optimally and are free from leaks.

Brake line compression fittings are an efficient way to connect two sections of steel brake line together. They create a tight seal between the two sections of line, preventing any potential leakage.

However, it’s essential to note that compression fittings are not designed for the high pressures found in modern braking systems. Usually, they only hold 300-500 psi of pressure – sufficient enough for everyday driving but not enough to support the higher demands placed upon them by modern brake systems.

Many states have outlawed the use of compression fittings to repair brake lines on passenger vehicles. These fittings often burst under extreme pressure, leading to costly brake failure and accidents.

👀Look at this: 4 Wheel Disc Brake Master Cylinder