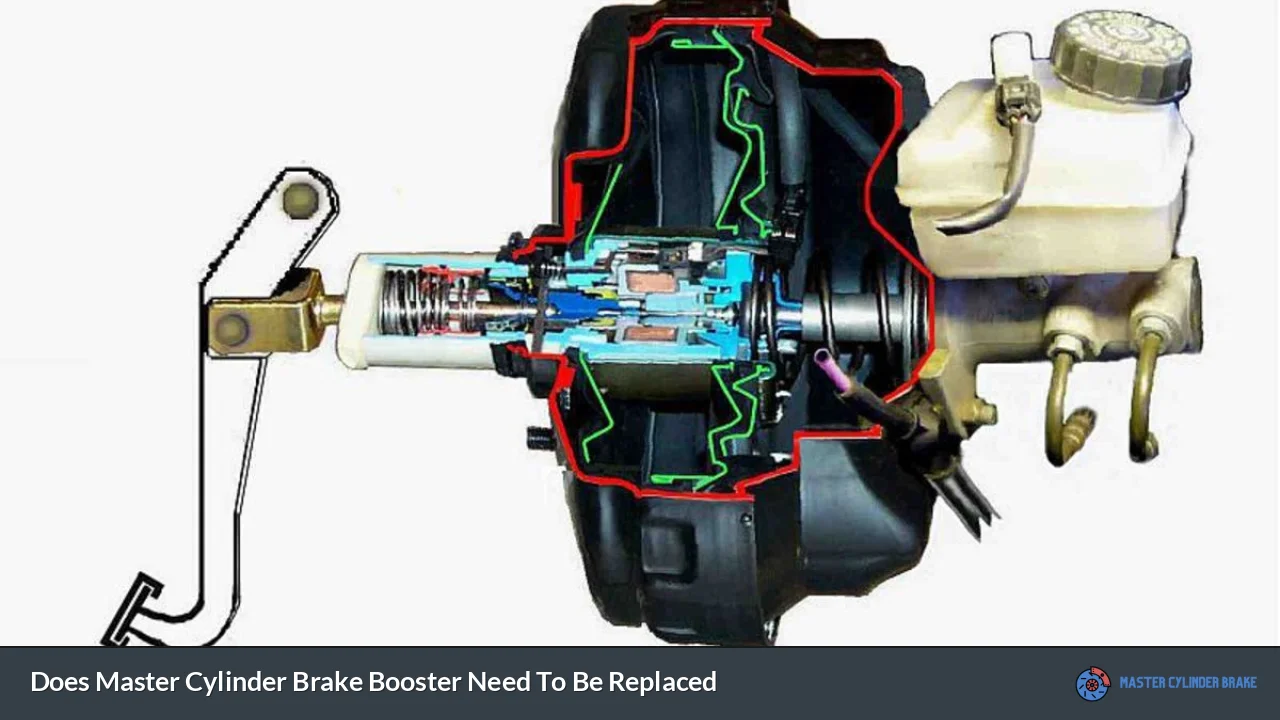

The master cylinder and brake booster are critical components of a vehicle’s braking system. While they work together to provide effective braking, they are separate parts that may not always need to be replaced simultaneously. Understanding when and why these components require replacement is crucial for maintaining optimal brake performance and safety.

The master cylinder converts the mechanical force from the brake pedal into hydraulic pressure, while the brake booster amplifies the force applied to the brake pedal, making it easier for the driver to stop the vehicle. These components can wear out over time or fail due to various factors, including age, mileage, and exposure to harsh conditions.

| Component | Function |

|---|---|

| Master Cylinder | Converts mechanical force to hydraulic pressure |

| Brake Booster | Amplifies force applied to brake pedal |

Signs of Master Cylinder Failure

Recognizing the signs of a failing master cylinder is crucial for timely replacement and maintaining brake system integrity. Some common indicators include:

- Spongy brake pedal: If the brake pedal feels soft or sinks to the floor when pressed, it may indicate a problem with the master cylinder.

- Brake fluid leaks: Visible brake fluid leaks under the vehicle or around the master cylinder are a clear sign of failure.

- Warning lights: The brake warning light on the dashboard may illuminate, indicating a problem with the braking system.

- Contaminated brake fluid: If the brake fluid appears dirty or has a burnt odor, it could suggest internal master cylinder issues.

- Uneven brake performance: If some wheels brake more effectively than others, it might be due to a faulty master cylinder.

When these symptoms occur, it’s essential to have the master cylinder inspected by a qualified mechanic. In many cases, replacement of the master cylinder alone may be sufficient to restore proper brake function. However, the decision to replace the brake booster as well depends on its condition and the overall state of the braking system.

Indications for Brake Booster Replacement

The brake booster typically has a longer lifespan than the master cylinder, but it can still fail or require replacement. Signs that your brake booster may need attention include:

- Hard brake pedal: If the brake pedal becomes significantly harder to press, it could indicate a failing brake booster.

- Increased stopping distance: A malfunctioning booster can lead to longer stopping distances, compromising safety.

- Hissing noises: A distinct hissing sound when applying or releasing the brakes may suggest a vacuum leak in the booster.

- Engine stalling: In some cases, a faulty brake booster can cause the engine to stall when the brakes are applied.

- Brake drag: If the brakes seem to drag or the vehicle doesn’t accelerate smoothly, it could be due to a stuck brake booster check valve.

While these symptoms may indicate a problem with the brake booster, they don’t necessarily mean that both the booster and master cylinder need replacement. A thorough inspection by a professional can determine whether one or both components require attention.

Factors Influencing Replacement Decisions

Several factors come into play when deciding whether to replace both the master cylinder and brake booster:

- Age and mileage of the vehicle: Older vehicles or those with high mileage may benefit from replacing both components as preventive maintenance.

- Extent of damage: If one component has failed catastrophically, it may have caused damage to the other, necessitating dual replacement.

- Cost considerations: While replacing both parts at once can be more cost-effective in terms of labor, it may not always be necessary if one component is still in good condition.

- Compatibility issues: In some cases, upgrading one component may require upgrading the other to ensure proper function and compatibility.

- Safety concerns: If there’s any doubt about the condition of either component, erring on the side of caution and replacing both can provide peace of mind.

It’s important to note that unnecessary replacement of functioning components can lead to additional costs and potential complications. Therefore, a professional diagnosis is crucial in making an informed decision.

Replacement Process Overview

When replacement is deemed necessary, the process typically involves the following steps:

1. Drain the brake fluid: The brake system must be drained of fluid before component removal.

2. Disconnect brake lines: Brake lines connected to the master cylinder are carefully disconnected.

3. Remove the master cylinder: The master cylinder is unbolted from the brake booster and removed.

4. Inspect the brake booster: The condition of the brake booster is assessed to determine if replacement is needed.

5. Replace components: Either the master cylinder alone or both the master cylinder and brake booster are replaced with new parts.

6. Reconnect and refill: Brake lines are reconnected, and the system is refilled with fresh brake fluid.

7. Bleed the brake system: Air is purged from the brake lines to ensure proper function.

8. Test and adjust: The braking system is tested and adjusted as necessary to ensure optimal performance.

This process requires specialized tools and expertise, making it a job best left to professional mechanics or experienced DIY enthusiasts with proper equipment and knowledge.

Preventive Maintenance and Longevity

To maximize the lifespan of your master cylinder and brake booster, consider the following preventive maintenance tips:

- Regular brake fluid changes: Fresh brake fluid helps prevent internal corrosion and maintains proper hydraulic function.

- Prompt leak repairs: Address any brake fluid leaks immediately to prevent damage to components and ensure safety.

- Routine inspections: Have your braking system inspected regularly as part of your vehicle’s maintenance schedule.

- Avoid aggressive braking: Smooth, gradual braking can reduce wear on brake components, including the master cylinder and booster.

- Address warning signs promptly: Don’t ignore symptoms of brake system issues; early intervention can prevent more extensive damage.

By following these practices, you can often extend the life of your braking system components and potentially avoid premature replacement of the master cylinder or brake booster.

FAQs About Does Master Cylinder Brake Booster Need To Be Replaced

- Can I replace just the master cylinder without changing the brake booster?

Yes, in many cases, you can replace only the master cylinder if the brake booster is still functioning properly. - How often should the master cylinder and brake booster be replaced?

There’s no set interval; replacement is typically based on performance and wear, often around 100,000-150,000 miles. - Is it more cost-effective to replace both components at the same time?

It can be more cost-effective in terms of labor, but it’s not always necessary if one component is still in good condition. - Can a faulty master cylinder damage the brake booster?

Yes, a leaking master cylinder can potentially damage the brake booster if brake fluid enters the booster’s vacuum chamber. - How long does it take to replace a master cylinder and brake booster?

The process typically takes 2-4 hours for a professional mechanic, depending on the vehicle model and complications.