The master cylinder and brake caliper are crucial components of a vehicle’s braking system, working together to convert the driver’s pedal input into stopping power. The master cylinder generates hydraulic pressure when the brake pedal is pressed, while the caliper uses this pressure to clamp the brake pads against the rotor. Understanding the typical lifespan of these parts is essential for maintaining a safe and effective braking system. While both components are designed for longevity, their durability can vary based on several factors including driving habits, environmental conditions, and maintenance practices.

The average lifespan of a master cylinder typically ranges from 60,000 to 200,000 miles, while brake calipers can last anywhere from 75,000 to 100,000 miles or more. However, these figures can fluctuate significantly depending on various circumstances. Regular inspection and maintenance are key to maximizing the longevity of these critical brake components. Let’s explore the factors that influence their lifespan and how to recognize when replacement might be necessary.

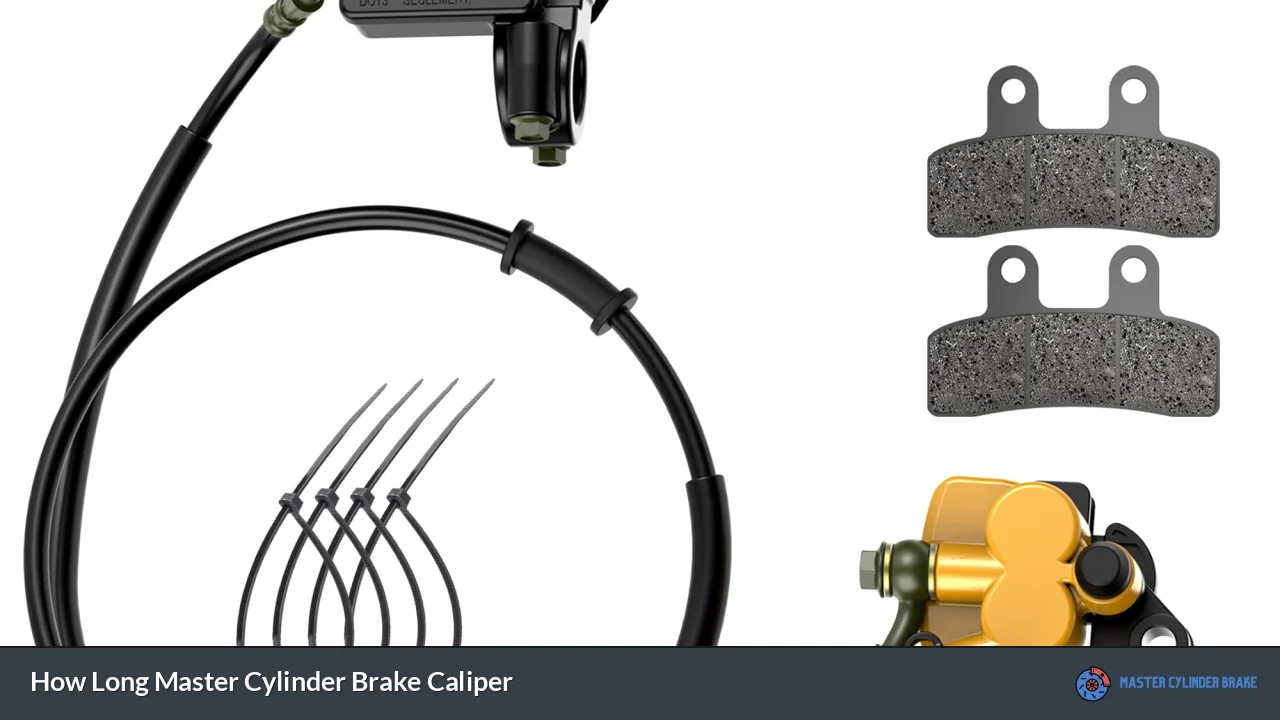

| Component | Average Lifespan |

|---|---|

| Master Cylinder | 60,000 – 200,000 miles |

| Brake Caliper | 75,000 – 100,000+ miles |

Factors Affecting Master Cylinder Lifespan

The master cylinder’s longevity is influenced by several key factors. Driving conditions play a significant role in determining how long a master cylinder will last. Vehicles frequently driven in stop-and-go traffic or in areas with many hills will experience more wear on the master cylinder due to increased brake usage. The quality of brake fluid used is another crucial factor. Regular brake fluid changes are essential as old or contaminated fluid can lead to internal corrosion of the master cylinder, significantly reducing its lifespan.

Environmental conditions also impact the master cylinder’s durability. Exposure to road salt and extreme temperatures can accelerate wear and tear. In colder climates, the freeze-thaw cycle can cause expansion and contraction of metal components, potentially leading to premature failure. Conversely, in hot climates, the increased heat can cause brake fluid to break down more quickly, affecting the master cylinder’s performance.

The frequency of brake system maintenance is perhaps the most critical factor in extending a master cylinder’s life. Regular brake fluid flushes, typically recommended every 2-3 years or 30,000 miles, can prevent the buildup of moisture and contaminants that can damage the master cylinder’s internal components. Ignoring these maintenance intervals can lead to a shortened lifespan and potentially costly repairs.

Manufacturing quality also plays a role in how long a master cylinder will last. Original equipment manufacturer (OEM) parts or high-quality aftermarket components tend to have better durability compared to cheaper alternatives. The materials used in construction, such as the quality of seals and internal components, can significantly affect the master cylinder’s resistance to wear and corrosion.

Lastly, driving habits can have a substantial impact on the master cylinder’s longevity. Aggressive braking, such as frequent hard stops or riding the brake pedal, can increase wear on the master cylinder. Smooth, anticipatory braking techniques can help reduce stress on the braking system, potentially extending the life of the master cylinder and other brake components.

Factors Affecting Brake Caliper Lifespan

Brake calipers are designed to be durable, but several factors can influence their lifespan. Driving conditions are a primary factor, with city driving typically causing more wear than highway driving due to the increased frequency of braking. Vehicles used in mountainous areas or for towing may experience accelerated caliper wear due to the increased demands placed on the braking system.

The quality of brake pads used can significantly impact caliper longevity. Low-quality brake pads can wear unevenly or produce excessive brake dust, which can accumulate in the caliper and cause sticking or seizure. Using brake pads recommended by the vehicle manufacturer or high-quality aftermarket options can help protect the calipers and extend their useful life.

Environmental factors play a crucial role in caliper durability. Exposure to road salt, water, and debris can lead to corrosion and premature wear. In coastal areas or regions where road salt is used extensively, calipers may require more frequent inspection and maintenance to prevent rust and ensure proper operation.

Regular maintenance is essential for maximizing caliper lifespan. This includes periodic inspection of the brake system, cleaning and lubricating caliper slide pins, and replacing brake fluid as recommended by the vehicle manufacturer. Neglecting these maintenance tasks can lead to stuck calipers, uneven pad wear, and potentially costly repairs.

The quality of brake fluid used is another critical factor. Brake fluid absorbs moisture over time, which can lead to internal corrosion of brake system components, including the calipers. Regular brake fluid changes, typically every 2-3 years or as specified in the vehicle’s maintenance schedule, can help prevent this issue and extend caliper life.

Driving habits also impact caliper longevity. Aggressive braking generates more heat, which can cause brake fluid to break down more quickly and potentially lead to caliper seal failure. Additionally, riding the brakes or frequent hard stops can accelerate wear on both the calipers and brake pads.

Lastly, the overall design and quality of the caliper itself plays a role in its lifespan. OEM calipers or high-quality aftermarket options typically offer better durability and performance compared to budget alternatives. The materials used in caliper construction, such as the quality of seals and pistons, can significantly affect their resistance to wear and environmental factors.

Signs of Master Cylinder Failure

Recognizing the signs of a failing master cylinder is crucial for maintaining a safe and effective braking system. One of the most common indicators is a spongy or soft brake pedal. This occurs when air enters the brake lines due to a leak in the master cylinder, reducing the hydraulic pressure needed for effective braking. If the brake pedal gradually sinks to the floor when held down, this could also indicate a failing master cylinder.

Another sign to watch for is uneven braking performance. If the vehicle pulls to one side when braking or if the brake pedal feels inconsistent, it could be due to a problem with the master cylinder. This uneven performance can occur when the master cylinder is unable to maintain consistent pressure across all brake lines.

Visible brake fluid leaks are a clear indication of master cylinder issues. Check for puddles or dampness under the vehicle, particularly near the driver’s side firewall where the master cylinder is typically located. Brake fluid has a distinctive odor and is usually clear or amber in color. If you notice a decrease in brake fluid levels without any visible external leaks, it could indicate an internal leak in the master cylinder.

A warning light on the dashboard related to the braking system can also signal potential master cylinder problems. Modern vehicles are equipped with sensors that can detect low brake fluid levels or abnormal pressure in the brake lines, both of which can be caused by a failing master cylinder.

In some cases, contaminated brake fluid can be a sign of master cylinder failure. If the brake fluid appears dirty, has particles floating in it, or has a burnt smell, it could indicate that the master cylinder’s seals are breaking down and contaminating the fluid. This contamination can lead to further damage to other brake system components if not addressed promptly.

Increased stopping distance is another potential indicator of master cylinder issues. If you find that your vehicle requires more distance to come to a complete stop than usual, it could be due to a loss of hydraulic pressure caused by a failing master cylinder. This symptom is particularly dangerous and should be addressed immediately to ensure safe vehicle operation.

Lastly, unusual noises when applying the brakes, such as a hissing sound, could indicate a leak in the master cylinder or brake booster. While not all brake noises are related to the master cylinder, any unusual sounds should be investigated promptly to determine their cause and ensure the safety of the braking system.

Signs of Brake Caliper Failure

Identifying the signs of brake caliper failure is crucial for maintaining a safe and efficient braking system. One of the most common indicators is uneven brake pad wear. If you notice that one brake pad is significantly more worn than the other on the same wheel, it could indicate a stuck caliper that’s not releasing properly. This uneven wear can lead to reduced braking performance and potentially damage the brake rotor.

Vehicle pulling to one side when braking is another clear sign of caliper issues. This occurs when one caliper is applying more pressure than the others, causing the vehicle to veer in the direction of the wheel with the most braking force. This symptom can be dangerous, especially during emergency braking situations, and should be addressed immediately.

Squealing or grinding noises when applying the brakes can also indicate caliper problems. While these sounds can be caused by worn brake pads, they may also occur if a caliper is stuck and causing the brake pad to constantly rub against the rotor. Persistent noise, especially when not applying the brakes, warrants immediate inspection.

Brake fluid leaks around the caliper are a serious sign of failure. Brake fluid is crucial for the proper operation of the caliper, and any leaks can lead to reduced braking performance. Look for wet spots or stains on the inside of the wheel or around the caliper itself. The brake fluid may appear clear to amber in color and have a distinctive odor.

Reduced braking performance or a spongy brake pedal can also indicate caliper issues. If a caliper is not functioning correctly, it may not apply sufficient pressure to the brake pads, resulting in longer stopping distances and a brake pedal that feels soft or requires more force to engage.

Visible damage or corrosion on the caliper is another sign to watch for. While some surface rust is normal, extensive corrosion or visible cracks in the caliper body indicate that replacement is necessary. Regular visual inspections can help catch these issues early.

Brake drag is a symptom where the vehicle seems to resist moving freely, even when the brake pedal is not applied. This can be caused by a caliper that’s not fully releasing, leading to increased fuel consumption and accelerated wear on brake components.

Lastly, excessive brake dust on one wheel compared to the others can indicate a sticking caliper. While some brake dust is normal, an unusually large amount on a single wheel may suggest that the caliper is not fully releasing, causing constant contact between the brake pad and rotor.

FAQs About How Long Master Cylinder Brake Caliper

- How often should I replace my vehicle’s master cylinder?

Master cylinders typically last 60,000 to 200,000 miles, but replacement depends on wear and maintenance. - Can brake calipers last the lifetime of a vehicle?

While possible, most calipers need replacement after 75,000 to 100,000 miles due to wear and environmental factors. - What maintenance can extend the life of brake components?

Regular brake fluid changes, caliper lubrication, and brake system inspections can significantly extend component life. - How do driving habits affect brake system longevity?

Aggressive braking and frequent stops in traffic can accelerate wear on both master cylinders and calipers. - Are OEM brake components better than aftermarket options?

OEM parts often offer better quality and fit, but high-quality aftermarket components can be equally reliable and sometimes more cost-effective.