Installing a master cylinder brake is a critical task that requires precision and attention to detail. This component plays a vital role in your vehicle’s braking system, converting the force applied to the brake pedal into hydraulic pressure that activates the brakes. A properly installed master cylinder ensures optimal brake performance and safety on the road. Whether you’re replacing a faulty unit or upgrading your braking system, understanding the installation process is crucial for any automotive enthusiast or professional mechanic.

The installation process involves several key steps, from preparing the work area to bleeding the brake system. It’s essential to follow manufacturer guidelines and use the correct tools to ensure a successful installation. While the specific details may vary depending on your vehicle make and model, the general principles remain consistent across most automotive applications.

Before diving into the installation process, it’s important to understand the two main types of master cylinders and their key differences:

| Single Circuit Master Cylinder | Dual Circuit Master Cylinder |

|---|---|

| Older design, less common in modern vehicles | Standard in most modern vehicles |

| Controls all brakes with one hydraulic circuit | Uses two separate hydraulic circuits for redundancy |

| Less safe if circuit fails | Provides backup if one circuit fails |

| Simpler construction | More complex design |

Now, let’s explore the step-by-step process of installing a master cylinder brake, ensuring your vehicle’s braking system operates at peak performance.

Preparation and Safety Measures

Before beginning the installation process, it’s crucial to prioritize safety and proper preparation. Start by parking your vehicle on a level surface and engaging the parking brake. This ensures stability throughout the installation process. Next, disconnect the negative terminal of the battery to prevent any electrical mishaps while working on the braking system.

Gather all necessary tools and materials before starting. You’ll typically need:

- New master cylinder

- Brake fluid (as specified by your vehicle manufacturer)

- Wrench set

- Socket set

- Line wrench

- Brake bleeding kit

- Clean rags or shop towels

- Safety glasses

- Disposable gloves

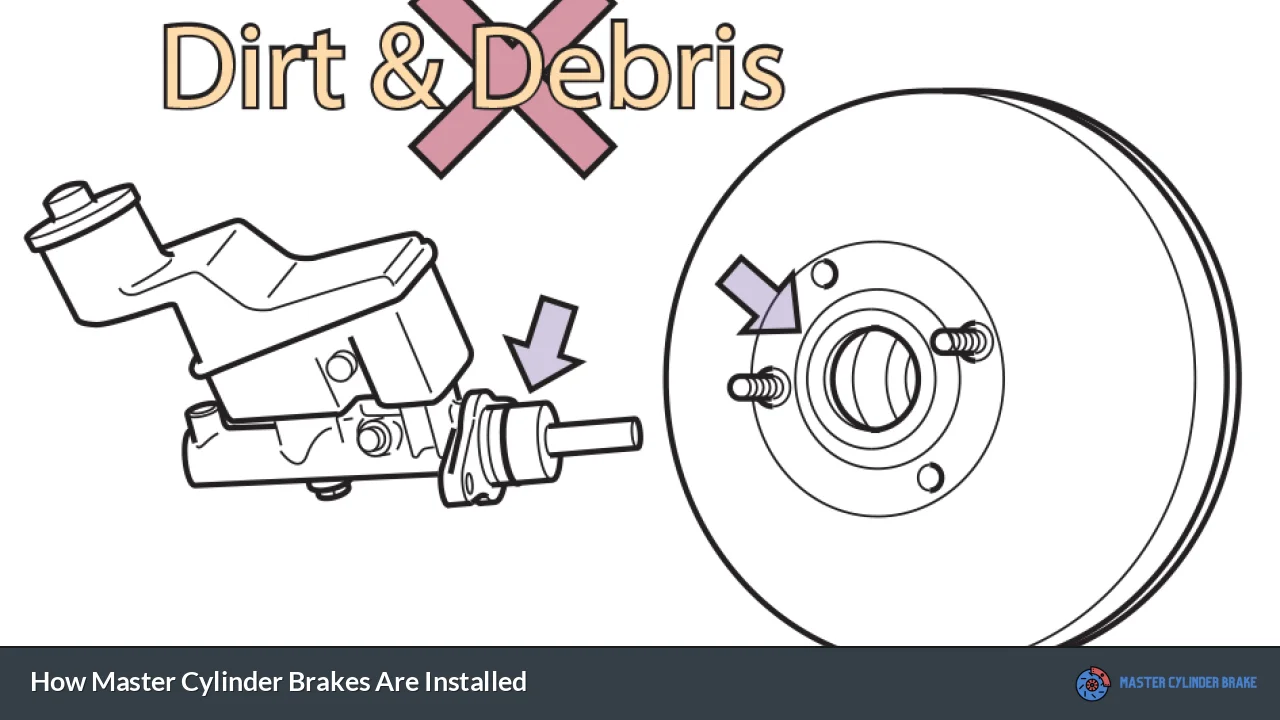

It’s important to work in a well-ventilated area, as brake fluid can emit strong fumes. Additionally, brake fluid is highly corrosive and can damage painted surfaces, so keep a supply of clean rags or shop towels handy to quickly clean up any spills.

Before removing the old master cylinder, it’s a good practice to take clear photos of the brake line connections. This will serve as a reference during reassembly, ensuring you reconnect everything correctly. Also, consider labeling the brake lines to avoid confusion during installation.

Lastly, consult your vehicle’s service manual for any model-specific instructions or torque specifications. Different vehicles may have slight variations in the installation process, and following manufacturer guidelines is crucial for a successful installation.

Removing the Old Master Cylinder

The first step in installing a new master cylinder is removing the old one. Begin by locating the master cylinder, which is typically mounted on the firewall in the engine compartment, directly in front of the driver’s seat. It’s connected to the brake booster, a large round canister that amplifies the force applied to the brake pedal.

Start by removing the brake fluid reservoir cap and using a turkey baster or syringe to remove as much brake fluid as possible from the reservoir. This minimizes spillage during the removal process. Next, disconnect the brake lines from the master cylinder using a line wrench. It’s crucial to use the correct tool to avoid rounding off the fittings.

Once the brake lines are disconnected, you’ll need to remove the mounting nuts that secure the master cylinder to the brake booster. These are usually accessible from inside the engine compartment. After removing the nuts, carefully pull the master cylinder away from the brake booster.

Be cautious of any remaining brake fluid in the master cylinder as you remove it. Have a drain pan ready to catch any spills. Inspect the brake booster push rod and the area around the mounting surface for any signs of leakage or damage. If you notice any issues with the brake booster, it may need to be replaced as well.

With the old master cylinder removed, take a moment to compare it with the new unit to ensure they match in terms of size, mounting points, and brake line fittings. If everything looks correct, you’re ready to move on to the next step: bench bleeding the new master cylinder.

Bench Bleeding the New Master Cylinder

Bench bleeding is a crucial step in the installation process that removes air from the master cylinder before it’s installed in the vehicle. This procedure helps ensure proper brake performance and reduces the time needed for system bleeding later on.

To bench bleed the new master cylinder:

- Secure the master cylinder in a vise, clamping it by the mounting flange

- Fill the reservoir with new brake fluid of the type specified for your vehicle

- Attach bench bleeding tubes or kit to the outlet ports

- Use a blunt tool to slowly depress the piston, watching for air bubbles in the fluid

- Release the piston and allow it to return slowly

- Repeat this process until no more air bubbles are visible in the fluid

It’s important to take your time during this process and avoid introducing new air into the system. Some master cylinders come with plugs for the outlet ports; if yours does, remove them before bench bleeding and replace them afterward to prevent fluid loss during installation.

Once you’ve successfully bench bled the master cylinder, it’s ready for installation in your vehicle. Remember to keep the master cylinder level during transfer to prevent air from re-entering the system.

Installing the New Master Cylinder

With the new master cylinder properly bench bled, you’re ready to install it in your vehicle. Begin by carefully positioning the master cylinder against the brake booster, ensuring the push rod is properly aligned. This step is critical for proper brake function, so take your time to get it right.

Next, thread the mounting nuts onto the studs protruding from the brake booster. Hand-tighten them initially to ensure proper alignment. Once you’re satisfied with the positioning, use a torque wrench to tighten the nuts to the manufacturer’s specified torque. Over-tightening can damage the master cylinder or brake booster, while under-tightening can lead to leaks or improper operation.

After securing the master cylinder, it’s time to reconnect the brake lines. Remove any plugs you may have installed after bench bleeding, and carefully thread the brake lines into their respective ports. Use a line wrench to tighten the fittings, being careful not to cross-thread or over-tighten them.

Once all connections are secure, refill the brake fluid reservoir to the proper level with fresh fluid. Be sure to use the type of brake fluid specified for your vehicle, as mixing different types can cause damage to the braking system.

At this point, it’s a good idea to check all your connections one more time. Ensure all fittings are tight, the master cylinder is securely mounted, and there are no visible leaks or issues. Taking a few extra minutes for a thorough inspection can save you a lot of trouble down the road.

Bleeding the Brake System

After installing the new master cylinder, the final step is bleeding the entire brake system to remove any air that may have entered during the installation process. This is crucial for ensuring proper brake performance and pedal feel.

Start by locating the brake bleeder screws on each wheel. You’ll typically begin with the wheel farthest from the master cylinder and work your way closer. The usual order is:

- Right rear

- Left rear

- Right front

- Left front

For each wheel:

- Have an assistant slowly pump the brake pedal several times, then hold it down

- Open the bleeder screw slightly to allow fluid and air to escape

- Close the bleeder screw before the pedal reaches the floor

- Repeat this process until no more air bubbles are visible in the fluid

It’s important to keep an eye on the fluid level in the master cylinder reservoir throughout this process. If it gets too low, you risk introducing more air into the system. Top off the reservoir as needed with fresh brake fluid.

After bleeding all four wheels, check the brake pedal feel. It should be firm and consistent. If the pedal feels spongy or soft, you may need to repeat the bleeding process.

Finally, double-check all connections for leaks, top off the brake fluid reservoir to the proper level, and replace the reservoir cap. Take the vehicle for a careful test drive in a safe area to ensure the brakes are functioning correctly before returning to normal driving conditions.

FAQs About How Master Cylinder Brakes Are Installed

- How long does it take to install a master cylinder?

Installation typically takes 2-4 hours for an experienced mechanic, depending on the vehicle model. - Can I install a master cylinder myself?

While possible, it’s recommended to have a professional do it due to the complexity and safety implications. - How often should a master cylinder be replaced?

Master cylinders usually last 60,000-100,000 miles, but should be replaced if leaking or malfunctioning. - What are signs of a failing master cylinder?

Common signs include a sinking brake pedal, uneven brake performance, and visible fluid leaks. - Is it necessary to bleed brakes after replacing the master cylinder?

Yes, bleeding the entire brake system is crucial to remove air and ensure proper brake function.