The master cylinder is the heart of a vehicle’s braking system, converting mechanical force from the brake pedal into hydraulic pressure. This crucial component enables drivers to slow or stop their vehicles efficiently and safely. When you press the brake pedal, the master cylinder pressurizes brake fluid, which then activates the brake calipers or wheel cylinders at each wheel. Understanding how master cylinder brakes work is essential for proper vehicle maintenance and troubleshooting brake issues.

Master cylinders typically consist of a fluid reservoir, pistons, seals, and brake lines. Most modern vehicles use a dual-circuit master cylinder design for added safety, with separate circuits controlling the front and rear brakes. This redundancy ensures that if one circuit fails, the other can still provide some braking power. The master cylinder works in conjunction with other brake system components like the brake booster, calipers, rotors, and brake pads to bring your vehicle to a stop.

| Component | Function |

|---|---|

| Fluid Reservoir | Stores brake fluid |

| Pistons | Create hydraulic pressure |

| Seals | Prevent fluid leakage |

| Brake Lines | Transmit pressure to wheels |

Master Cylinder Components

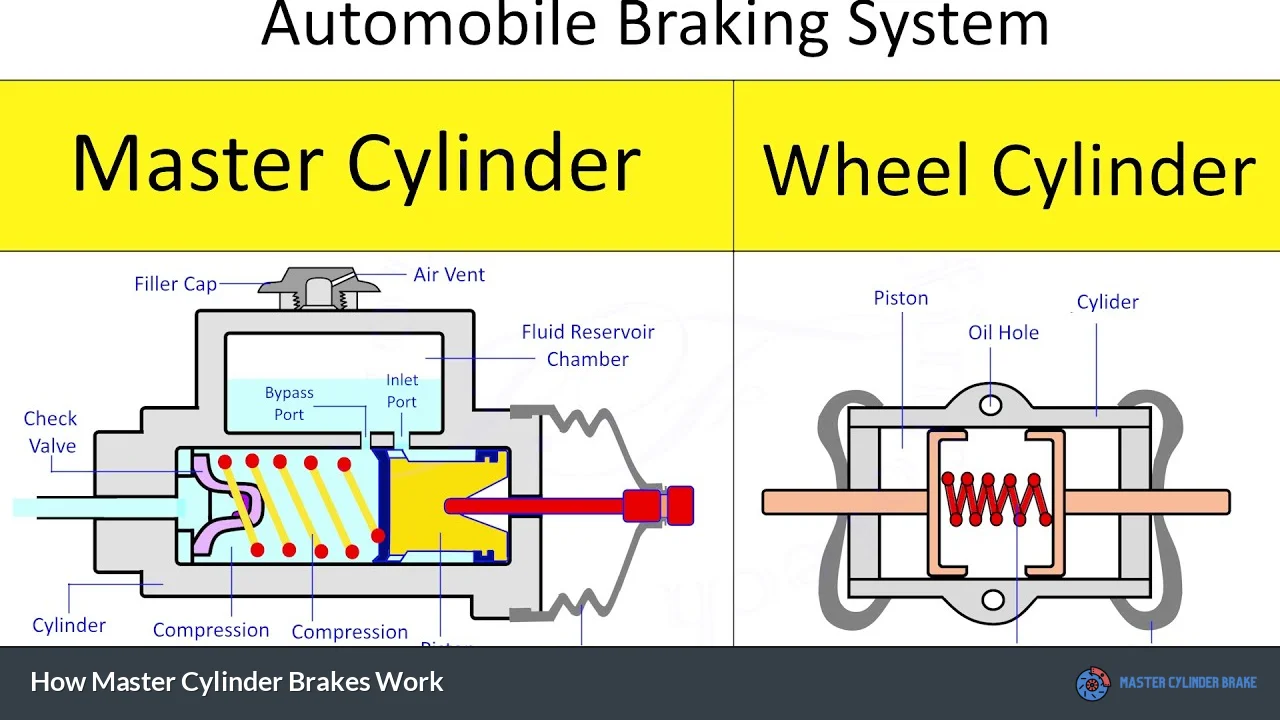

The master cylinder consists of several key components that work together to generate and distribute hydraulic pressure throughout the braking system. Understanding these parts is crucial for diagnosing and maintaining your vehicle’s brakes.

The fluid reservoir sits atop the master cylinder and stores brake fluid. It’s typically made of translucent plastic, allowing you to check fluid levels easily. The reservoir has a cap with small vent holes to maintain atmospheric pressure and prevent vacuum formation. Some vehicles have a single reservoir, while others have separate chambers for the front and rear brake circuits.

Inside the master cylinder, you’ll find one or more pistons. These cylindrical components move back and forth within the bore of the master cylinder. When you press the brake pedal, it pushes a rod that moves the primary piston. In a dual-circuit system, this primary piston then pushes a secondary piston. The movement of these pistons creates the hydraulic pressure needed to activate the brakes.

Seals play a critical role in the master cylinder’s function. There are typically two types of seals: primary and secondary. The primary seal moves with the piston and creates the initial pressure in the system. The secondary seal helps maintain pressure and prevents fluid from leaking past the piston. These seals are usually made of rubber or similar materials designed to withstand the harsh conditions inside the brake system.

Brake lines connect the master cylinder to the rest of the braking system. These steel or flexible rubber lines carry pressurized brake fluid to the calipers or wheel cylinders at each wheel. In a dual-circuit system, separate lines run to the front and rear brakes, providing an extra layer of safety in case one circuit fails.

The pushrod connects the brake pedal (often via a brake booster) to the master cylinder. When you press the brake pedal, the pushrod moves the primary piston, initiating the braking process. Some master cylinders also include a brake light switch that activates your vehicle’s brake lights when the pedal is pressed.

How Master Cylinder Brakes Function

The operation of master cylinder brakes relies on the principles of hydraulics to multiply force and distribute it evenly throughout the braking system. When you press the brake pedal, a series of events occurs within milliseconds to bring your vehicle to a stop.

As you apply pressure to the brake pedal, the pushrod moves forward, pushing the primary piston inside the master cylinder. This action creates pressure within the fluid-filled chamber behind the piston. In a dual-circuit system, the primary piston’s movement also pushes the secondary piston forward.

The movement of these pistons pressurizes the brake fluid in the master cylinder. This pressure is then transmitted through the brake lines to the wheel cylinders or calipers at each wheel. The hydraulic pressure can reach up to 1,000 psi or more during hard braking, demonstrating the significant forces at work in your braking system.

At the wheels, this hydraulic pressure causes the pistons in the brake calipers (for disc brakes) or wheel cylinders (for drum brakes) to move. In disc brake systems, the caliper pistons push the brake pads against the rotor, creating friction that slows the wheel. For drum brakes, the wheel cylinder pistons push the brake shoes against the inside of the drum, achieving the same effect.

One of the key advantages of this hydraulic system is its ability to multiply force. A relatively small input force on the brake pedal can generate a much larger force at the wheels, thanks to the principles of hydraulics and the mechanical advantage provided by the pedal linkage and often a brake booster.

When you release the brake pedal, return springs in the master cylinder pull the pistons back to their rest position. This action reduces the hydraulic pressure in the system, allowing the brake pads or shoes to retract slightly from the rotor or drum. Some master cylinders also incorporate quick take-up valves that help reduce the distance the brake pedal must travel before engaging the brakes, improving pedal feel and responsiveness.

Types of Master Cylinders

There are several types of master cylinders used in modern vehicles, each with its own characteristics and applications. Understanding these different types can help you better diagnose brake issues and make informed decisions about repairs or upgrades.

The most common type is the tandem master cylinder, also known as a dual-circuit master cylinder. This design features two pistons in a single bore, controlling separate hydraulic circuits. Typically, one circuit operates the front brakes while the other controls the rear brakes. This redundancy is a crucial safety feature, ensuring that if one circuit fails, the other can still provide some braking power.

Some older vehicles or specialized applications may use a single-circuit master cylinder. As the name suggests, this type has only one piston and controls all the brakes through a single hydraulic circuit. While simpler, this design is less safe as a failure in any part of the system can result in complete brake loss.

Portless master cylinders are a more recent innovation, often used in vehicles with anti-lock braking systems (ABS). These cylinders don’t have the traditional fluid ports found in older designs. Instead, they use a center valve arrangement that helps prevent air from entering the system during normal operation. This design can improve brake pedal feel and reduce the likelihood of brake fade.

For high-performance applications, some vehicles use a racing-style master cylinder. These are typically larger in diameter and have a shorter stroke, providing better pedal feel and more precise brake control. They’re often adjustable, allowing drivers to fine-tune brake bias between the front and rear wheels.

Some heavy-duty vehicles or those with air brakes use a hydraulic-pneumatic master cylinder. This type uses compressed air to create hydraulic pressure, combining the advantages of both air and hydraulic brake systems.

| Master Cylinder Type | Primary Use |

|---|---|

| Tandem (Dual-Circuit) | Most modern passenger vehicles |

| Single-Circuit | Older vehicles, some motorcycles |

| Portless | Vehicles with ABS |

| Racing-Style | Performance and racing applications |

| Hydraulic-Pneumatic | Heavy-duty and commercial vehicles |

Maintenance and Troubleshooting

Proper maintenance of your vehicle’s master cylinder is crucial for ensuring safe and effective braking. Regular inspections and timely repairs can prevent many common brake issues and extend the life of your braking system.

One of the most important maintenance tasks is checking and replacing brake fluid. Over time, brake fluid can absorb moisture from the air, which lowers its boiling point and can lead to brake fade. Most manufacturers recommend changing brake fluid every 2-3 years. When checking the fluid level, look for any signs of contamination or discoloration. Clean, fresh brake fluid should be clear with a slight yellow tint.

Inspect the master cylinder and surrounding areas for any signs of fluid leaks. A leaking master cylinder can cause a loss of brake pressure and should be addressed immediately. Look for wet spots or stains on the cylinder itself, the brake booster, or the floor beneath the vehicle. If you notice a leak, have it repaired as soon as possible to prevent brake failure.

Pay attention to how your brake pedal feels. A spongy or soft pedal could indicate air in the brake lines, which requires bleeding the system. If the pedal sinks to the floor or feels different than usual, it could be a sign of a failing master cylinder or other brake system issues.

If you experience reduced braking power or notice that your vehicle pulls to one side when braking, it could be due to uneven pressure distribution from the master cylinder. This might require professional diagnosis and potentially replacing the master cylinder.

When troubleshooting brake issues, start with the basics. Check the brake fluid level and condition, inspect for leaks, and test the pedal feel. If these checks don’t reveal the problem, you may need to perform more advanced diagnostics, such as pressure testing the master cylinder or checking for internal leaks.

Remember that working on brakes can be dangerous due to the high pressures involved. If you’re not comfortable performing brake work yourself, it’s best to consult a professional mechanic. They have the tools and expertise to safely diagnose and repair brake system issues.

FAQs About How Master Cylinder Brakes Work

- How often should I replace my vehicle’s master cylinder?

Master cylinders typically last 60,000-100,000 miles, but can fail earlier due to contamination or wear. - Can I drive with a faulty master cylinder?

No, a faulty master cylinder can lead to complete brake failure and is extremely dangerous. - How do I know if my master cylinder is failing?

Signs include a sinking brake pedal, fluid leaks, or warning lights on your dashboard. - Can I replace a master cylinder myself?

It’s possible but not recommended unless you have experience with brake systems and proper bleeding techniques. - What causes a master cylinder to fail?

Common causes include seal wear, contaminated brake fluid, and internal corrosion of the cylinder bore.