Bleeding brakes through the master cylinder is a crucial maintenance task that ensures your vehicle’s braking system operates efficiently and safely. This process removes air bubbles from the brake lines, which can cause a spongy brake pedal and reduced braking performance. By following the correct steps, you can effectively bleed your brakes through the master cylinder, restoring optimal brake function and enhancing your vehicle’s safety on the road.

Proper brake bleeding is essential for maintaining the hydraulic pressure in your braking system. When air enters the brake lines, it compresses under pressure, leading to a loss of braking power. This can result in longer stopping distances and potentially dangerous situations while driving. By bleeding the brakes through the master cylinder, you can eliminate these air pockets and ensure that your brake pedal feels firm and responsive.

Before beginning the brake bleeding process, it’s important to understand the components involved and gather the necessary tools. Here’s a quick overview of what you’ll need:

| Tools | Materials |

|---|---|

| Wrench or socket set | Fresh brake fluid (DOT 3 or DOT 4) |

| Clear plastic tubing | Clean rags |

| Brake bleeder wrench | Disposable container |

| Jack and jack stands | Rubber gloves |

Preparing for Brake Bleeding

Before you start bleeding the brakes through the master cylinder, it’s crucial to properly prepare your vehicle and workspace. This preparation will ensure a smooth and efficient bleeding process while minimizing the risk of accidents or mistakes.

First, park your vehicle on a level surface and engage the parking brake. This will provide a stable platform for working on the brakes. Next, loosen the lug nuts on all four wheels before jacking up the vehicle. This step makes it easier to remove the wheels later if necessary. Using a jack, lift the vehicle and secure it on jack stands. Never rely solely on a jack to support the vehicle’s weight while working underneath it.

Once the vehicle is safely elevated, locate the master cylinder under the hood. It’s typically found on the driver’s side of the firewall, near the brake booster. Remove the cap from the master cylinder reservoir and check the brake fluid level. If it’s low, top it off with fresh brake fluid of the correct type (usually DOT 3 or DOT 4, as specified in your vehicle’s manual).

Next, identify the bleeder screws on each brake caliper or wheel cylinder. These small valves are usually located on the backside of the brake assembly. Clean the area around each bleeder screw with brake cleaner to prevent dirt from entering the system during the bleeding process.

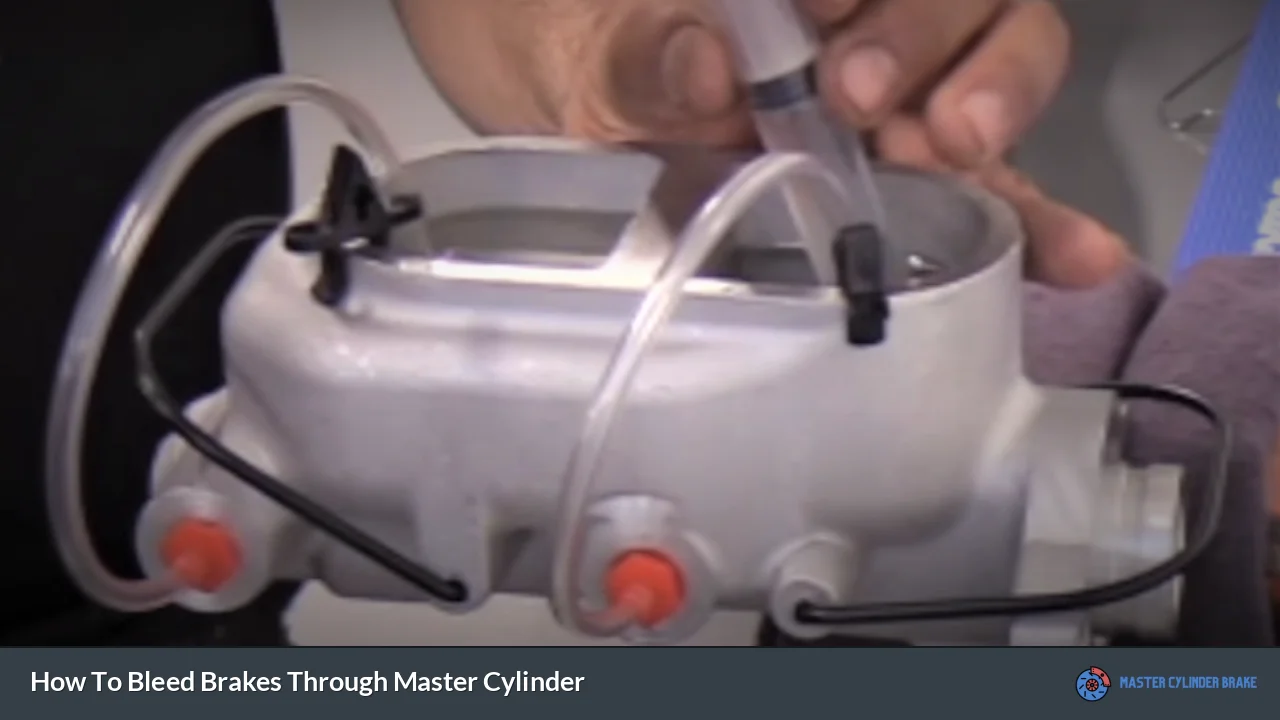

Prepare your brake bleeding kit by attaching a length of clear plastic tubing to a brake bleeder wrench. The other end of the tubing should be placed in a clean, empty container to catch the old brake fluid. This setup allows you to see the fluid as it’s expelled from the system, making it easier to identify when all the air bubbles have been removed.

Bleeding the Master Cylinder

Now that you’ve prepared your vehicle and workspace, it’s time to begin bleeding the master cylinder. This process is crucial for removing air from the brake system and ensuring proper brake performance.

Start by locating the brake lines that connect to the master cylinder. There are typically two or four lines, depending on your vehicle’s brake system configuration. You’ll need to bleed each line individually, starting with the one farthest from the master cylinder and working your way closer.

Begin with the brake line farthest from the driver’s side. Loosen the fitting connecting this line to the master cylinder using a line wrench. Be careful not to completely remove the fitting, as you only need to create a small gap for air to escape.

Next, have an assistant slowly depress the brake pedal. As they do this, you should see brake fluid and air bubbles emerging from the loosened fitting. Tighten the fitting before your assistant releases the pedal. This process forces air out of the master cylinder and replaces it with fresh brake fluid.

Repeat this process several times for each brake line, working your way towards the driver’s side. After each line has been bled, check the fluid level in the master cylinder reservoir and top it off as needed. It’s crucial to maintain the proper fluid level throughout the bleeding process to prevent air from being drawn back into the system.

Once you’ve bled all the lines at the master cylinder, it’s time to move on to bleeding the individual wheel cylinders or calipers. This step ensures that any remaining air in the brake lines is completely removed.

Bleeding Individual Brake Lines

After bleeding the master cylinder, you’ll need to bleed each individual brake line to ensure all air is removed from the system. This process requires patience and attention to detail, but it’s essential for achieving optimal brake performance.

Start with the brake that’s farthest from the master cylinder, which is typically the rear passenger-side wheel. Locate the bleeder screw on the wheel cylinder or caliper and attach your clear plastic tubing to it. Place the other end of the tubing in a container partially filled with fresh brake fluid.

Have your assistant slowly pump the brake pedal several times, then hold it firmly pressed down. While they maintain pressure on the pedal, use your brake bleeder wrench to open the bleeder screw about a quarter turn. You should see fluid and possibly air bubbles flowing through the tubing into the container.

As the fluid flows, the brake pedal will slowly sink to the floor. Before it reaches the floor, have your assistant tell you so you can close the bleeder screw. This prevents air from being drawn back into the system. Repeat this process until you see a steady stream of clear fluid without any air bubbles.

Move on to the next farthest brake from the master cylinder, typically the rear driver-side wheel. Repeat the bleeding process for this brake, then move to the front passenger-side and finally the front driver-side brake. Remember to check the master cylinder fluid level frequently throughout this process and top it off as needed.

After bleeding all four brakes, test the brake pedal. It should feel firm and responsive. If the pedal still feels spongy, you may need to repeat the bleeding process or check for leaks in the system.

Finalizing the Brake Bleeding Process

Once you’ve completed bleeding all four brakes, it’s crucial to properly finalize the process to ensure your braking system is functioning optimally and safely. This final stage involves a series of checks and adjustments that will give you confidence in your newly bled brakes.

First, double-check all bleeder screws to ensure they are tightly closed. A loose bleeder screw can allow air to enter the system, undoing all your hard work. Use your brake bleeder wrench to give each screw a final tightening, but be careful not to over-tighten and strip the threads.

Next, inspect the master cylinder reservoir one last time. The fluid level should be at the “Full” line. If it’s not, top it off with fresh brake fluid. Be sure to use the correct type of fluid as specified in your vehicle’s manual. Never mix different types of brake fluid, as this can cause damage to the brake system components.

With the fluid levels correct, it’s time to test the brake pedal. Start the engine and press the brake pedal firmly several times. The pedal should feel solid and responsive, with no sponginess or excessive travel. If the pedal still feels soft or sinks to the floor, you may need to repeat the bleeding process or check for leaks in the system.

Perform a visual inspection of all brake lines, hoses, and fittings for any signs of leakage. Even a small leak can introduce air into the system and compromise braking performance. If you spot any leaks, address them immediately before driving the vehicle.

Once you’re satisfied with the brake pedal feel and have confirmed there are no leaks, take your vehicle for a test drive in a safe area. Start with gentle brake applications and gradually increase to firmer stops. Pay attention to how the brakes feel and listen for any unusual noises. The brakes should be responsive and provide consistent stopping power without pulling to one side.

After your test drive, perform one final check of the brake fluid level and inspect for any signs of leakage. If everything looks good, you can be confident that you’ve successfully bled your brakes through the master cylinder.

FAQs About How To Bleed Brakes Through Master Cylinder

- How often should I bleed my brakes?

Brake bleeding is typically recommended every 2-3 years or when brake components are replaced. - Can I bleed brakes without a helper?

While possible with a pressure bleeder, having an assistant makes the process much easier and more effective. - What happens if air gets into the brake lines?

Air in brake lines can cause a spongy brake pedal and reduced braking performance, potentially compromising safety. - How do I know if my brakes need bleeding?

Signs include a soft or spongy brake pedal, decreased braking performance, or after replacing brake components. - Can I reuse old brake fluid when bleeding brakes?

No, always use fresh, clean brake fluid when bleeding brakes to ensure optimal performance and safety.