The master cylinder is a critical component of your vehicle’s braking system, responsible for converting the force applied to the brake pedal into hydraulic pressure that activates the brakes. When this vital part fails, it can lead to serious safety issues and compromised braking performance. Understanding how to repair a master cylinder is essential for maintaining your vehicle’s safety and can save you money on costly replacements.

Master cylinder repair typically involves addressing issues such as fluid leaks, internal seal failures, or piston problems. The repair process requires careful attention to detail and a methodical approach to ensure all components are properly cleaned, inspected, and reassembled. While the task may seem daunting, with the right tools and knowledge, many car enthusiasts and DIY mechanics can successfully repair a master cylinder.

Before diving into the repair process, it’s important to recognize the signs of a failing master cylinder and understand the basic components involved. Here’s a quick overview of what you’ll need to know:

| Component | Function |

|---|---|

| Reservoir | Stores brake fluid |

| Pistons | Create hydraulic pressure |

| Seals | Prevent fluid leakage |

| Brake lines | Distribute hydraulic pressure |

Diagnosing Master Cylinder Issues

Before attempting any repairs, it’s crucial to accurately diagnose the problem with your master cylinder. Common symptoms of a failing master cylinder include a spongy brake pedal, brake fluid leaks, or uneven braking performance. To begin the diagnostic process, visually inspect the master cylinder for any signs of fluid leakage or corrosion. Check the brake fluid level in the reservoir and look for any discoloration or contamination.

Next, test the brake pedal feel. If the pedal sinks to the floor or feels spongy, this could indicate air in the brake lines or a failing master cylinder. Pay attention to any changes in brake performance, such as increased stopping distance or a pulling sensation when braking. These symptoms may point to a problem with the master cylinder or other components of the braking system.

It’s important to note that some issues may mimic master cylinder problems but are actually caused by other brake system components. For example, a faulty brake booster can cause similar symptoms to a failing master cylinder. Therefore, it’s essential to perform a thorough inspection of the entire braking system before concluding that the master cylinder is the culprit.

Gathering Tools and Materials

Before beginning the repair process, gather all necessary tools and materials. Having everything on hand will make the job smoother and help prevent delays. Here’s a list of items you’ll typically need:

- Socket set and wrenches

- Screwdrivers (flathead and Phillips)

- Pliers

- Brake fluid (check your vehicle’s manual for the correct type)

- Brake cleaner

- Clean rags

- Safety glasses and gloves

- Jack and jack stands

- Brake bleeding kit

- New master cylinder rebuild kit or replacement unit

It’s crucial to use the correct type of brake fluid for your vehicle, as mixing incompatible fluids can cause damage to the braking system. Always refer to your vehicle’s manual or consult with a professional if you’re unsure about which fluid to use.

Removing the Master Cylinder

The first step in repairing your master cylinder is to remove it from the vehicle. This process may vary slightly depending on your vehicle make and model, but the general steps are as follows:

- Disconnect the negative battery terminal to prevent electrical shorts

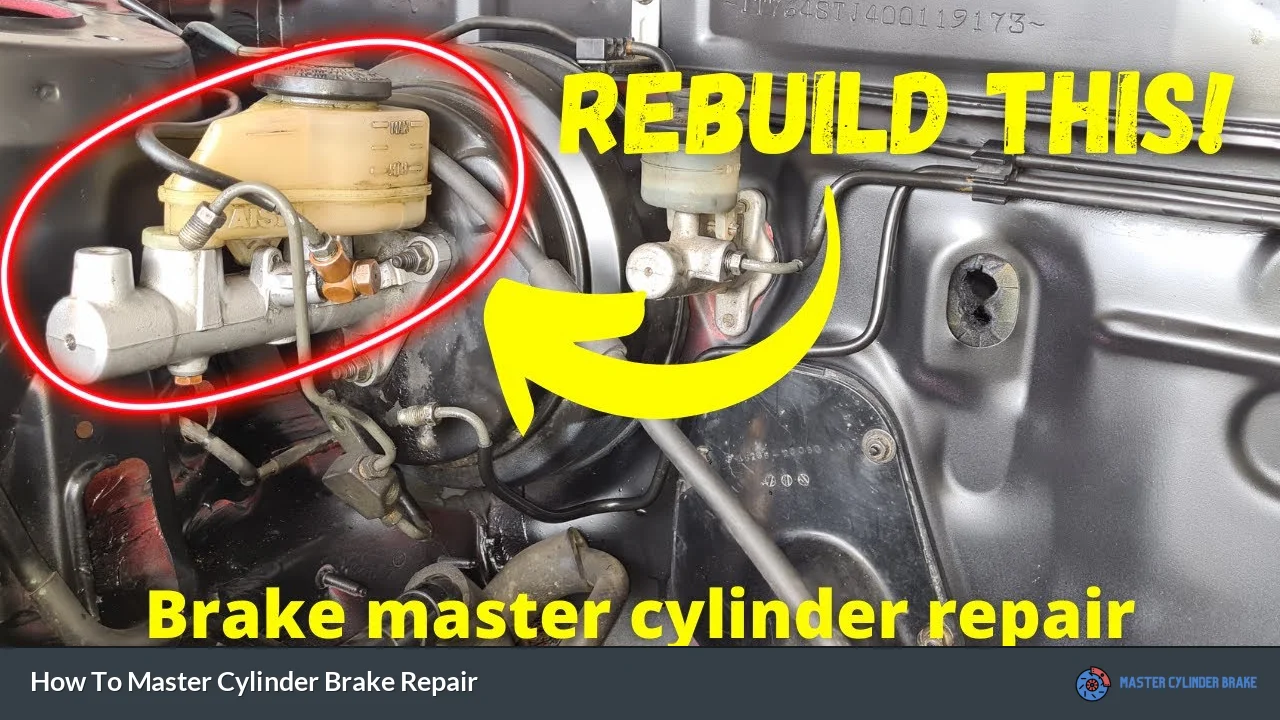

- Locate the master cylinder, typically mounted on the brake booster

- Remove any components obstructing access to the master cylinder

- Disconnect the brake lines from the master cylinder, using a line wrench to avoid damaging the fittings

- Remove the mounting bolts securing the master cylinder to the brake booster

- Carefully pull the master cylinder away from the brake booster

Be prepared for some brake fluid spillage when disconnecting the brake lines. Use a drain pan to catch any fluid and dispose of it properly, as brake fluid can damage paint and is harmful to the environment.

Disassembling the Master Cylinder

Once the master cylinder is removed, you can begin disassembling it for repair. This process requires careful attention to detail and cleanliness. Follow these steps:

- Remove the reservoir from the master cylinder body

- Take note of the orientation of all components as you disassemble them

- Remove the snap ring or retaining clip that holds the pistons in place

- Carefully extract the pistons, springs, and seals from the cylinder bore

- Inspect all components for wear, damage, or corrosion

During disassembly, it’s crucial to work in a clean environment to prevent contamination of the brake system. Any dirt or debris introduced during the repair process can cause serious issues later on.

Cleaning and Inspecting Components

Thorough cleaning and inspection of all master cylinder components is essential for a successful repair. Use brake cleaner and clean rags to remove all traces of old brake fluid and debris from the cylinder bore, pistons, and other parts. Inspect the cylinder bore for any signs of scoring, pitting, or corrosion that could prevent proper sealing.

Check the pistons for wear or damage, paying close attention to the areas where the seals make contact. Examine all springs for signs of weakness or deformation. If any components show significant wear or damage, it’s best to replace them rather than risk a failure after reassembly.

Rebuilding the Master Cylinder

With all components cleaned and inspected, you can begin rebuilding the master cylinder. This process involves replacing all seals and any worn components with new parts from your rebuild kit. Follow these steps:

- Lubricate all new seals with clean brake fluid before installation

- Carefully install the new seals onto the pistons, ensuring they are seated correctly

- Reassemble the pistons, springs, and other components in the correct order

- Replace the snap ring or retaining clip to secure the assembly

- Reattach the reservoir to the master cylinder body

It’s crucial to handle all components with care during reassembly to avoid damaging the new seals or other parts. Take your time and double-check that everything is installed correctly before moving on to the next step.

Bench Bleeding the Master Cylinder

Before reinstalling the master cylinder, it’s important to bench bleed it to remove any air from the system. This process ensures that the master cylinder will function properly when installed. To bench bleed the master cylinder:

- Secure the master cylinder in a vise or suitable holding device

- Attach brake lines or bleeding kit adapters to the outlet ports

- Fill the reservoir with new brake fluid

- Use a tool to slowly depress the pistons, allowing fluid to flow through the lines

- Repeat this process until no air bubbles are visible in the fluid

Bench bleeding is a critical step that helps prevent air from entering the brake lines when the master cylinder is reinstalled. Skipping this step can lead to a spongy brake pedal and poor braking performance.

Reinstalling the Master Cylinder

With the master cylinder rebuilt and bench bled, you can now reinstall it in your vehicle. Follow these steps:

- Position the master cylinder against the brake booster

- Secure it with the mounting bolts, tightening them to the manufacturer’s specifications

- Reconnect the brake lines, being careful not to cross-thread the fittings

- Refill the reservoir with brake fluid

- Bleed the entire brake system to remove any remaining air

After reinstallation, it’s crucial to thoroughly bleed the brake system to ensure all air is removed from the lines. This typically involves bleeding each brake caliper or wheel cylinder in a specific order, as outlined in your vehicle’s service manual.

Testing and Final Adjustments

Once the master cylinder is reinstalled and the brake system is bled, it’s time to test your work. Start by checking for any leaks around the master cylinder and brake line connections. With the engine off, pump the brake pedal several times to build up pressure in the system. The pedal should feel firm and not sink to the floor.

Next, start the engine and test the brakes at low speeds in a safe area. Pay attention to the pedal feel and braking performance. If everything feels normal, gradually increase your speed and braking force to ensure the system is working correctly under various conditions.

If you encounter any issues such as a spongy pedal or poor braking performance, recheck your work and consider consulting a professional if problems persist.

FAQs About How To Master Cylinder Brake Repair

- How often should a master cylinder be replaced?

Master cylinders typically last 60,000 to 100,000 miles, but can fail sooner due to contamination or wear. - Can I drive with a faulty master cylinder?

It’s not safe to drive with a faulty master cylinder as it can lead to brake failure. - How long does it take to repair a master cylinder?

A skilled DIYer can typically complete the repair in 2-4 hours, depending on experience and vehicle complexity. - What causes a master cylinder to fail?

Common causes include seal wear, contaminated brake fluid, and internal corrosion. - Is it better to rebuild or replace a master cylinder?

Rebuilding can be cost-effective, but replacement may be preferable for severely worn or damaged units.