Replacing a brake master cylinder is a critical maintenance task that ensures your vehicle’s braking system functions properly. This component is responsible for converting the force applied to the brake pedal into hydraulic pressure, which activates the brake calipers or wheel cylinders. A faulty master cylinder can lead to brake failure, making it essential to replace it promptly when issues arise.

The process of replacing a master cylinder involves several steps, from preparing the vehicle and removing the old unit to installing and bleeding the new one. While it’s a task that can be accomplished by experienced DIY mechanics, it requires careful attention to detail and adherence to safety procedures. Improper installation can result in brake system failure, so it’s crucial to follow the correct steps and use the appropriate tools.

Before beginning the replacement process, it’s important to gather all necessary tools and materials, including the new master cylinder, brake fluid, wrenches, and a brake bleeding kit. Safety should be a top priority, so always work on a level surface, use proper jack stands, and wear protective gear.

| Tools Needed | Materials Required |

|---|---|

| Socket set and ratchet | New master cylinder |

| Line wrench set | Brake fluid |

| Pliers | Brake cleaner |

| Screwdriver | Shop towels |

| Brake bleeding kit | Thread locker |

Preparing for Master Cylinder Replacement

The first step in replacing your brake master cylinder is proper preparation. This involves ensuring your vehicle is safely positioned and all necessary tools and materials are at hand. Begin by parking your vehicle on a flat, level surface and engaging the parking brake. It’s crucial to work on a stable surface to prevent any accidents during the replacement process.

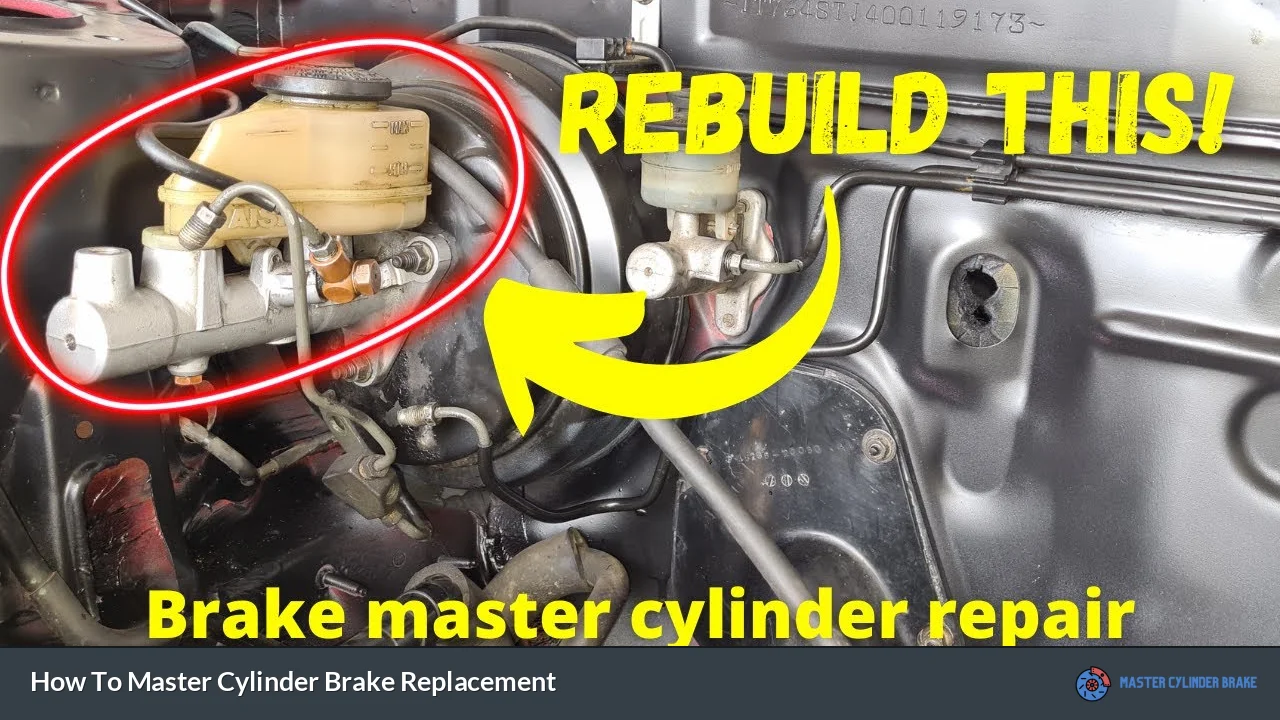

Next, open the hood and locate the master cylinder. It’s typically found on the driver’s side of the engine compartment, attached to the brake booster. Before you start any work, it’s essential to relieve the pressure in the brake system. This can be done by pumping the brake pedal several times with the engine off until it becomes firm.

Now, it’s time to prepare the work area. Place a large drain pan under the master cylinder to catch any brake fluid that may spill during the replacement process. Brake fluid is highly corrosive and can damage paint, so it’s crucial to protect surrounding areas with shop towels or plastic sheeting.

Before disconnecting any components, take a moment to inspect the master cylinder and surrounding area. Look for signs of leakage, corrosion, or damage. This inspection can provide valuable information about the condition of your braking system and help identify any additional components that may need attention.

Lastly, disconnect the negative terminal of the battery. This safety precaution prevents any electrical shorts while you’re working on the brake system. With these preparatory steps complete, you’re ready to begin the actual replacement process.

Removing the Old Master Cylinder

Removing the old master cylinder is a critical step in the replacement process. Start by locating the brake fluid reservoir, which is typically mounted on top of the master cylinder. Using a turkey baster or syringe, remove as much brake fluid as possible from the reservoir. This will minimize spillage when you disconnect the brake lines.

Next, identify the brake lines connected to the master cylinder. These are typically two or four metal lines that carry brake fluid to the wheels. Using a line wrench, carefully loosen the fittings on these lines. It’s important to use a line wrench rather than a standard open-end wrench to avoid rounding off the fittings. As you disconnect each line, brake fluid will likely drip out, so keep your drain pan in place and have shop towels ready.

Once the brake lines are disconnected, you’ll need to remove the master cylinder from the brake booster. This usually involves removing two nuts or bolts that secure the master cylinder to the booster. These fasteners are often accessible from inside the vehicle, under the dashboard. Use a socket wrench to remove these fasteners, being careful not to drop them into the engine compartment.

With the fasteners removed, you should be able to pull the master cylinder away from the brake booster. However, be prepared for some resistance, as there may be a vacuum seal between the two components. If necessary, gently pry the master cylinder away from the booster using a flat screwdriver, being careful not to damage the mating surfaces.

As you remove the old master cylinder, pay attention to any gaskets or seals between it and the brake booster. These may need to be replaced when installing the new unit. Also, take note of how the master cylinder is oriented and how the brake lines are routed. This will help ensure proper installation of the new unit.

Finally, inspect the brake booster and the area around it for any signs of brake fluid leakage or damage. If you notice any issues with the brake booster, it may be necessary to replace this component as well. With the old master cylinder removed, you’re now ready to prepare and install the new unit.

Installing the New Master Cylinder

Before installing the new master cylinder, it’s crucial to bench bleed the unit. This process removes air from the master cylinder, ensuring proper function once installed. To bench bleed, secure the master cylinder in a vise and attach the supplied bleeding kit or makeshift bleeder tubes to the outlet ports. Fill the reservoir with new brake fluid and use a blunt tool to slowly depress the piston, allowing fluid to circulate through the tubes and back into the reservoir. Continue this process until no air bubbles are visible in the fluid.

Once the new master cylinder is bled, you’re ready to install it. Begin by comparing the new unit to the old one, ensuring they are identical in terms of mounting points and brake line connections. If there’s a gasket between the master cylinder and brake booster, make sure to transfer it to the new unit or use a new one if provided.

Carefully position the new master cylinder against the brake booster, aligning the mounting holes. Thread the mounting nuts or bolts by hand to avoid cross-threading, then use a socket wrench to tighten them to the manufacturer’s specified torque. Over-tightening can damage the master cylinder or brake booster, so use a torque wrench if available.

Next, reconnect the brake lines to the new master cylinder. It’s crucial to connect each line to its correct port on the master cylinder. Tighten the fittings using a line wrench, being careful not to over-tighten, which can damage the fittings or the master cylinder itself. Once all lines are connected, double-check that they are secure but not overly tight.

After the master cylinder is installed and all connections are made, refill the brake fluid reservoir with new fluid. Use the type of brake fluid specified in your vehicle’s manual, as using the wrong type can cause damage to the brake system components.

Finally, reconnect the negative battery terminal and prepare to bleed the entire brake system. This final step is crucial for removing any air that may have entered the system during the replacement process.

Bleeding the Brake System

Bleeding the brake system is the final and crucial step in master cylinder replacement. This process removes air from the brake lines, ensuring proper brake function. Start by locating the brake bleeder screws on each wheel. These are typically found on the brake calipers for disc brakes or on the wheel cylinders for drum brakes.

Begin with the brake furthest from the master cylinder, which is usually the right rear wheel. Have an assistant inside the vehicle to pump the brake pedal. Open the bleeder screw slightly and have your assistant slowly pump the brake pedal. As they push down, you’ll see fluid and air bubbles coming out of the bleeder screw. Close the screw before your assistant releases the pedal. Repeat this process until you see only clear fluid without air bubbles.

Move to the next furthest wheel (usually left rear) and repeat the process. Continue to the right front and finally the left front wheel. Throughout this process, keep a close eye on the fluid level in the master cylinder reservoir, topping it off as needed. If the reservoir runs dry, you’ll introduce air into the system and have to start over.

After bleeding all four wheels, check the brake pedal feel. It should be firm and not spongy. If the pedal feels soft, repeat the bleeding process. Once you’re satisfied with the pedal feel, take the vehicle for a careful test drive in a safe area. Apply the brakes at various speeds to ensure they’re working correctly.

Remember, brake bleeding can be messy, so keep plenty of shop towels on hand and be prepared to clean up any spilled brake fluid immediately. Brake fluid can damage paint and other surfaces if left to sit.

FAQs About How To Master Cylinder Brake Replacement

- How do I know if my master cylinder needs replacement?

Signs include a sinking brake pedal, brake fluid leaks, or uneven brake performance. - Can I replace the master cylinder myself?

Yes, if you have mechanical experience and proper tools, but professional help is recommended for safety. - How long does it take to replace a master cylinder?

Typically 2-4 hours, depending on experience and vehicle model. - What type of brake fluid should I use?

Use the type specified in your vehicle’s manual, usually DOT 3 or DOT 4. - How often should a master cylinder be replaced?

There’s no set interval; replace when signs of failure appear or around 100,000 miles as preventive maintenance.