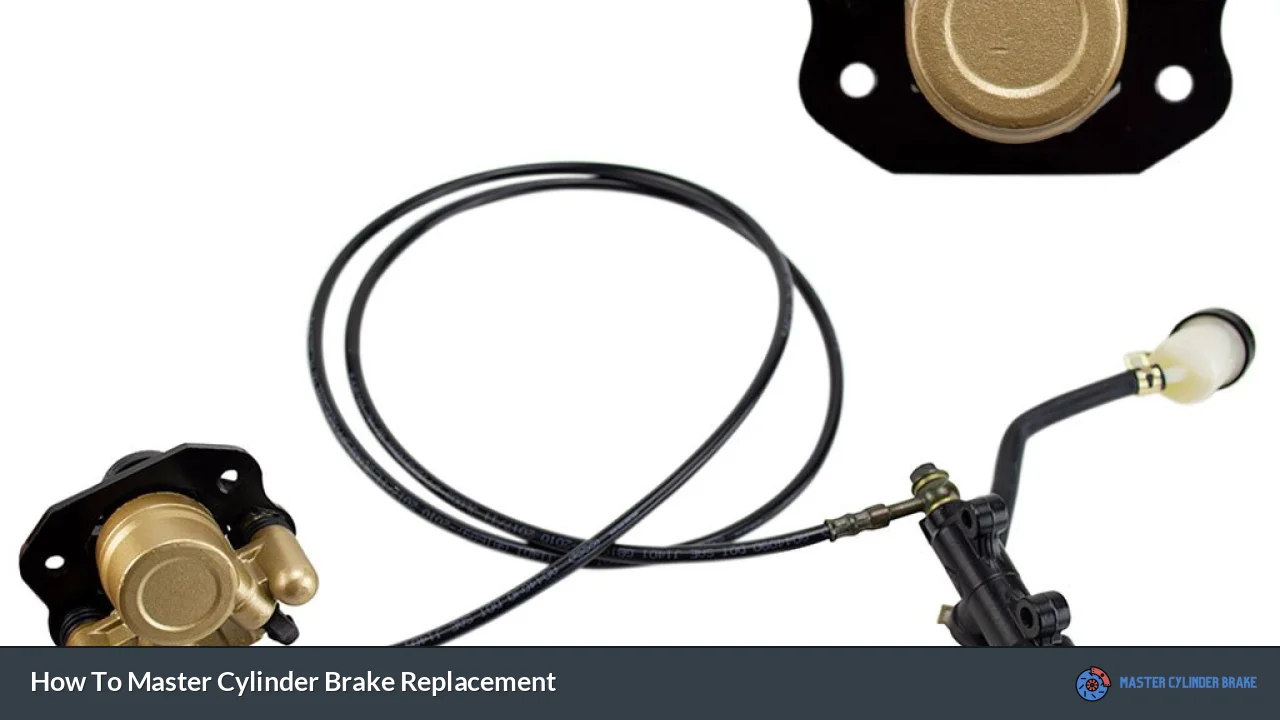

The master cylinder and brake caliper are two distinct but interconnected components of a vehicle’s braking system. While they work together to enable effective braking, they serve different functions and are located in separate parts of the car. The master cylinder converts the mechanical force from the brake pedal into hydraulic pressure, while the brake caliper uses that pressure to clamp the brake pads against the rotor, creating friction to slow or stop the vehicle.

Understanding the relationship between these two critical brake components is essential for proper vehicle maintenance and troubleshooting brake issues. Let’s explore the key differences and how they work together to ensure your vehicle stops safely and efficiently.

| Master Cylinder | Brake Caliper |

|---|---|

| Converts mechanical force to hydraulic pressure | Applies brake pads to rotor using hydraulic pressure |

| Located near the brake pedal | Located at each wheel |

| Contains brake fluid reservoir | Houses brake pads and pistons |

Master Cylinder Function and Components

The master cylinder is the heart of the hydraulic brake system. It’s typically located in the engine compartment, mounted on the firewall, and connected directly to the brake pedal. When you press the brake pedal, it activates a push rod in the master cylinder, which then moves a piston (or pistons in a dual-circuit system) inside the cylinder bore.

The main components of a master cylinder include:

- Cylinder bore

- Pistons (primary and secondary in dual-circuit systems)

- Seals and O-rings

- Brake fluid reservoir

- Push rod

- Return springs

As the piston moves, it pressurizes the brake fluid in the cylinder. This pressurized fluid is then sent through brake lines to the brake calipers at each wheel. The master cylinder’s design ensures that even if one brake circuit fails, the other can still provide some braking power, which is a critical safety feature.

Modern vehicles typically use a tandem master cylinder design, which has two separate chambers controlling two independent hydraulic circuits. This dual-circuit setup enhances safety by providing a backup if one circuit fails. The bore size of the master cylinder is crucial, as it affects the amount of fluid displaced and the pedal effort required for braking.

Master Cylinder Maintenance

Proper maintenance of the master cylinder is essential for safe vehicle operation. This includes:

- Regularly checking brake fluid levels

- Inspecting for leaks around the master cylinder and brake lines

- Replacing brake fluid according to manufacturer recommendations

- Addressing any signs of brake system malfunction promptly

Brake fluid contamination or air in the system can significantly impair the master cylinder’s performance. If you notice a spongy brake pedal or decreased braking efficiency, it may indicate issues with the master cylinder or air in the brake lines.

Brake Caliper Function and Types

The brake caliper is the component that houses the brake pads and pistons. It’s mounted over the brake rotor at each wheel. When hydraulic pressure from the master cylinder reaches the caliper, it forces the pistons to push the brake pads against the rotor, creating friction that slows or stops the wheel’s rotation.

There are two main types of brake calipers:

- Fixed calipers

- Floating (or sliding) calipers

Fixed calipers have pistons on both sides of the rotor and don’t move relative to the rotor. They provide more even pad wear and are often used in high-performance applications. Floating calipers, on the other hand, have pistons on only one side and move slightly as the brakes are applied, which helps center the caliper over the rotor.

The key components of a brake caliper include:

- Caliper housing

- Pistons

- Brake pads

- Slide pins (in floating calipers)

- Bleeder screws

- Dust boots

Brake calipers work in conjunction with the brake rotors (also called discs) to create the friction necessary for braking. The caliper’s design must balance factors like heat dissipation, pad wear, and braking force to ensure optimal performance.

Brake Caliper Maintenance

Regular maintenance of brake calipers is crucial for safe and effective braking. This includes:

- Inspecting brake pads for wear and replacing when necessary

- Lubricating slide pins on floating calipers

- Checking for fluid leaks or piston sticking

- Cleaning and inspecting caliper mounting hardware

Sticking calipers can cause uneven brake pad wear and reduced braking efficiency. If you notice your vehicle pulling to one side when braking or unusual noises coming from the wheels, it may indicate caliper issues that require attention.

Interaction Between Master Cylinder and Brake Caliper

The master cylinder and brake calipers work together as part of an integrated hydraulic braking system. When you press the brake pedal, the force is multiplied by the brake booster (in most modern vehicles) before being applied to the master cylinder. The master cylinder then converts this mechanical force into hydraulic pressure.

This pressurized brake fluid travels through brake lines to each wheel’s brake caliper. The caliper pistons extend, pushing the brake pads against the rotor. The amount of pressure applied at the pedal directly affects the clamping force of the calipers on the rotors.

Key aspects of this interaction include:

- Brake fluid incompressibility: Allows for efficient force transmission

- Proportioning valves: Distribute braking force between front and rear wheels

- Anti-lock Braking System (ABS): Modulates brake pressure to prevent wheel lock-up

The sizing relationship between the master cylinder and brake calipers is critical for proper brake system performance. A larger master cylinder bore will require more pedal effort but provide greater fluid volume, while a smaller bore will give a firmer pedal feel but may not provide enough fluid volume for some brake setups.

Troubleshooting Brake System Issues

When diagnosing brake problems, it’s important to consider both the master cylinder and calipers:

- Soft brake pedal: Could indicate air in the lines, failing master cylinder, or leaking calipers

- Pulling to one side: Might be caused by a sticking caliper or uneven brake pad wear

- Brake fluid loss: Check both master cylinder and calipers for leaks

- Reduced braking power: Could be due to a failing master cylinder or worn brake pads

Always consult a professional mechanic for brake system repairs, as improper maintenance can lead to brake failure and serious safety risks.

FAQs About Is Master Cylinder Brake Caliper

- Can a faulty master cylinder cause brake calipers to stick?

Yes, a failing master cylinder can cause uneven pressure distribution, potentially leading to caliper sticking. - How often should brake calipers be replaced?

Brake calipers typically last 75,000 to 100,000 miles but may need earlier replacement if damaged or sticking. - What are signs of a failing master cylinder?

Signs include a sinking brake pedal, uneven braking, brake fluid leaks, and warning light activation. - Can I replace just one brake caliper?

It’s recommended to replace calipers in pairs to ensure even braking performance on both sides of the axle. - How does ABS affect master cylinder and caliper operation?

ABS modulates pressure from the master cylinder to the calipers to prevent wheel lock-up during hard braking.