The master cylinder brake pads are a crucial component of a vehicle’s braking system, working in tandem with the master cylinder to ensure safe and effective stopping power. These pads play a vital role in converting the hydraulic pressure generated by the master cylinder into the mechanical force needed to slow down or stop a vehicle. Understanding how master cylinder brake pads function is essential for maintaining your vehicle’s braking performance and safety.

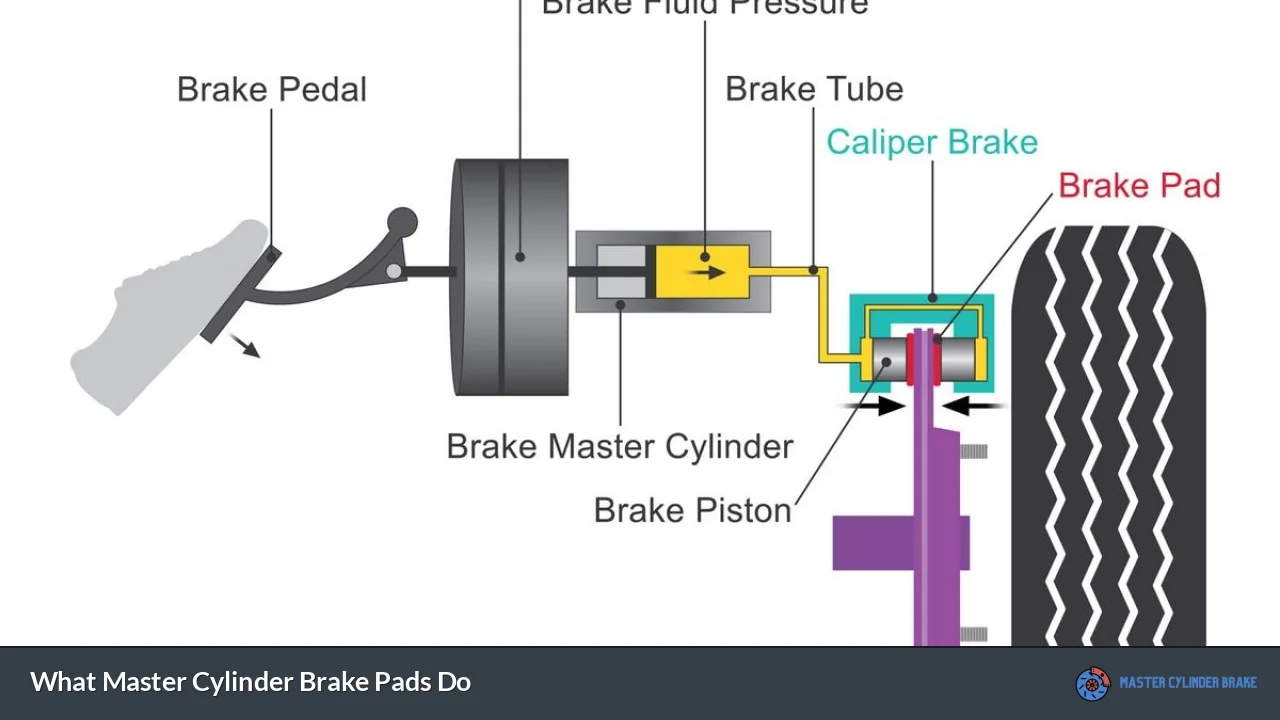

Master cylinder brake pads are designed to create friction against the brake rotors or drums, effectively slowing the rotation of the wheels. When you press the brake pedal, the master cylinder pushes brake fluid through the brake lines, activating the brake calipers or wheel cylinders. This action causes the brake pads to clamp down on the rotors or press against the drums, creating the friction necessary to slow or stop your vehicle.

| Component | Function |

|---|---|

| Master Cylinder | Generates hydraulic pressure |

| Brake Pads | Create friction to slow wheels |

Types of Master Cylinder Brake Pads

There are several types of master cylinder brake pads available, each with its own set of characteristics and performance attributes. The most common types include:

1. Semi-metallic brake pads: These pads are made from a mixture of metal fibers, friction modifiers, and bonding agents. They offer excellent heat dissipation and durability, making them ideal for high-performance vehicles and heavy-duty applications. Semi-metallic pads typically contain 30-65% metal content, providing robust braking power and long-lasting performance.

2. Ceramic brake pads: Composed of ceramic fibers, bonding agents, and small amounts of metal, these pads offer quiet operation and low dust production. They’re known for their excellent heat dissipation properties and consistent performance across a wide range of temperatures. Ceramic pads are often preferred for luxury vehicles and daily drivers due to their clean and quiet operation.

3. Organic brake pads: Made from natural materials such as rubber, glass, and Kevlar fibers, organic pads are the softest type available. They’re known for their quiet operation and low cost but tend to wear faster than other types. Organic pads are often used in light-duty vehicles and are ideal for normal driving conditions.

4. Low-metallic brake pads: These pads contain a small amount of metal, typically 10-30%, mixed with organic compounds. They offer a good balance between performance and cost, providing improved heat transfer and durability compared to organic pads while being more affordable than semi-metallic or ceramic options.

5. Sintered brake pads: Primarily used in motorcycles and high-performance vehicles, sintered pads are made by fusing metal particles under high heat and pressure. They offer exceptional durability and performance in extreme conditions but can be noisy and may cause increased wear on brake rotors.

Each type of brake pad has its own set of advantages and disadvantages, and the choice often depends on factors such as vehicle type, driving style, and budget considerations.

How Master Cylinder Brake Pads Work

The operation of master cylinder brake pads is a complex process that involves several components working in harmony. Here’s a step-by-step breakdown of how these pads function:

1. Pedal activation: When you press the brake pedal, it activates the master cylinder.

2. Hydraulic pressure: The master cylinder generates hydraulic pressure in the brake lines, pushing brake fluid through the system.

3. Caliper activation: The pressurized fluid reaches the brake calipers, causing them to clamp down on the brake rotors.

4. Pad contact: As the calipers squeeze, they push the brake pads against the spinning rotor surface.

5. Friction generation: The contact between the pads and rotors creates friction, which converts the vehicle’s kinetic energy into heat.

6. Vehicle deceleration: This friction slows the rotation of the wheels, ultimately decelerating the vehicle.

7. Heat dissipation: The heat generated during braking is dissipated through the brake rotors and surrounding air.

8. Pad retraction: When you release the brake pedal, the hydraulic pressure decreases, and the brake pads retract slightly from the rotor surface.

This process occurs rapidly and repeatedly during normal driving conditions, highlighting the importance of high-quality brake pads that can withstand the stress and heat generated during braking.

Factors Affecting Master Cylinder Brake Pad Performance

Several factors can influence the performance and longevity of master cylinder brake pads:

- Driving habits: Aggressive driving, frequent hard braking, and stop-and-go traffic can accelerate pad wear.

- Vehicle weight: Heavier vehicles require more braking force, potentially leading to faster pad wear.

- Brake system design: The overall design of the braking system, including rotor size and caliper type, can affect pad performance.

- Environmental conditions: Extreme temperatures, road salt, and debris can impact pad wear and effectiveness.

- Pad material: Different pad materials offer varying levels of performance, durability, and heat resistance.

- Rotor condition: Warped or unevenly worn rotors can cause uneven pad wear and reduced braking efficiency.

- Brake fluid quality: Contaminated or low-quality brake fluid can affect the hydraulic system’s performance, indirectly impacting pad function.

- Caliper maintenance: Stuck or poorly maintained calipers can cause uneven pad wear and reduced braking performance.

Understanding these factors can help vehicle owners and mechanics make informed decisions about brake pad selection and maintenance, ensuring optimal braking performance and safety.

Maintenance and Replacement of Master Cylinder Brake Pads

Proper maintenance and timely replacement of master cylinder brake pads are crucial for ensuring the safety and performance of your vehicle’s braking system. Here are some key points to consider:

- Regular inspections: Visually inspect your brake pads every 10,000 to 15,000 miles or as recommended by your vehicle manufacturer.

- Thickness measurements: Use a brake pad thickness gauge to measure the remaining pad material. Most pads should be replaced when they reach 3-4 mm in thickness.

- Listen for warning signs: Many brake pads come with built-in wear indicators that produce a squealing noise when the pads are nearing the end of their lifespan.

- Even wear: Check for even wear across all pads. Uneven wear may indicate problems with the calipers or rotors.

- Rotor inspection: When replacing pads, always inspect the rotors for scoring, warping, or other damage. Resurface or replace rotors as needed.

- Use quality parts: Always use high-quality brake pads that meet or exceed your vehicle manufacturer’s specifications.

- Professional installation: If you’re not comfortable replacing brake pads yourself, have them installed by a qualified mechanic.

- Break-in period: After installing new pads, follow the manufacturer’s break-in procedure to ensure proper seating and optimal performance.

- Fluid check: When replacing pads, check the brake fluid level and condition. Replace fluid if it’s dark or contaminated.

- System bleeding: If the brake system is opened during pad replacement, it may need to be bled to remove any air bubbles.

Regular maintenance and timely replacement of brake pads not only ensure your safety but can also prevent more costly repairs down the road by protecting other components of the braking system.

FAQs About What Master Cylinder Brake Pads Do

- How often should I replace my master cylinder brake pads?

Typically, brake pads should be replaced every 30,000 to 70,000 miles, depending on driving habits and pad material. - Can I mix different types of brake pads on my vehicle?

It’s not recommended to mix pad types, as it can lead to uneven braking performance and potentially dangerous situations. - How do I know if my master cylinder is affecting my brake pads?

Signs include a spongy brake pedal, uneven pad wear, or brake fluid leaks near the master cylinder. - Are ceramic brake pads better than semi-metallic ones?

Ceramic pads are quieter and produce less dust, but semi-metallic pads often provide better performance in high-heat situations. - Can worn brake pads damage my vehicle’s rotors?

Yes, severely worn pads can cause scoring or grooving on the rotors, potentially requiring rotor replacement.