The master cylinder brake system is a crucial component of a vehicle’s braking mechanism, responsible for converting the mechanical force applied to the brake pedal into hydraulic pressure. This pressure is then distributed to the wheel cylinders or calipers, enabling the vehicle to slow down or stop. The master cylinder serves as the heart of the hydraulic brake system, ensuring that braking force is evenly distributed to all wheels for safe and efficient stopping power.

When a driver presses the brake pedal, the master cylinder pressurizes brake fluid in the system. This pressurized fluid travels through brake lines to activate the brakes at each wheel. The master cylinder’s design allows it to maintain consistent pressure throughout the brake system, even if there’s a leak in one part of the circuit. This fail-safe feature is critical for maintaining some braking capability in case of partial system failure.

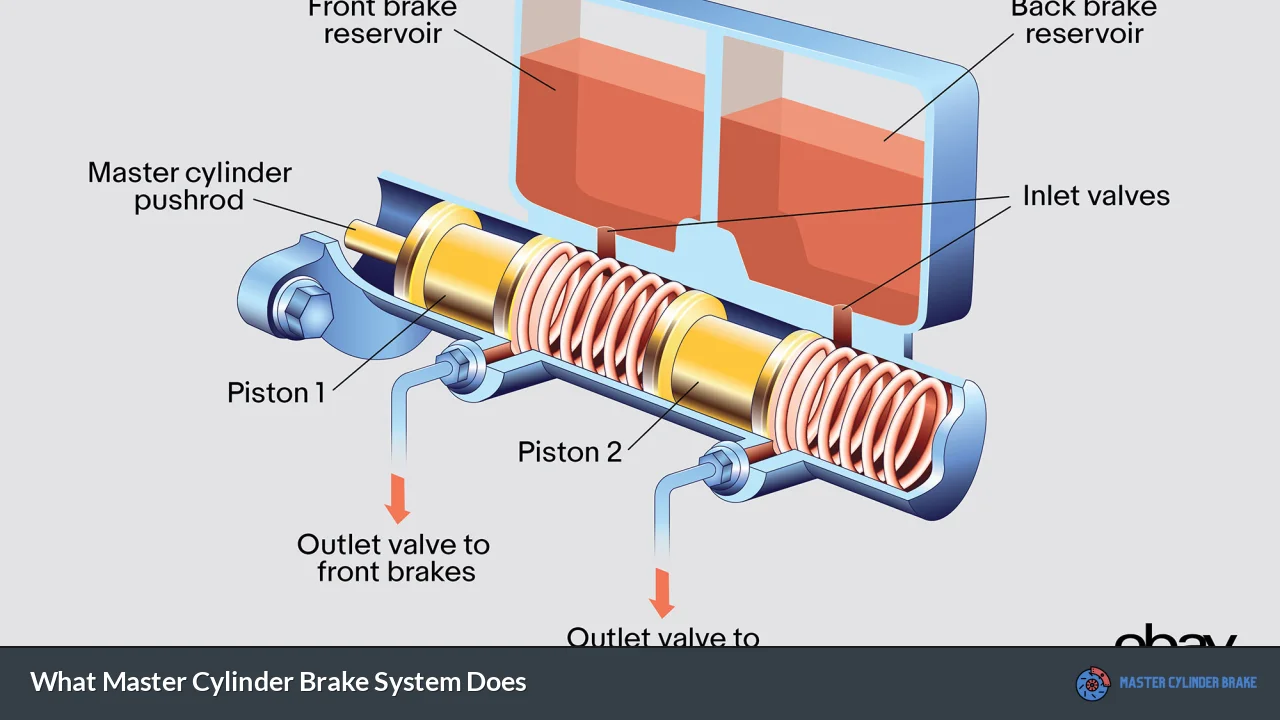

Modern vehicles typically use a dual-circuit master cylinder, which provides an additional layer of safety. This design separates the front and rear brake circuits, ensuring that if one circuit fails, the other can still provide some braking power. The master cylinder’s role in vehicle safety cannot be overstated, as it directly impacts a car’s ability to stop quickly and safely in various driving conditions.

| Component | Function |

|---|---|

| Reservoir | Stores brake fluid |

| Primary Piston | Pressurizes front brake circuit |

| Secondary Piston | Pressurizes rear brake circuit |

| Seals | Prevent fluid leakage |

Master Cylinder Components and Operation

The master cylinder consists of several key components that work together to create and distribute hydraulic pressure. The main parts include the fluid reservoir, pistons, seals, and brake lines. Understanding how these components interact is essential for grasping the full functionality of the master cylinder brake system.

The fluid reservoir sits atop the master cylinder and stores the brake fluid. It’s designed with a cap that allows for pressure equalization and easy fluid level checks. The reservoir feeds brake fluid to the cylinder bores, ensuring a constant supply of fluid for the braking system. It’s crucial to maintain the proper fluid level in the reservoir to prevent air from entering the system, which could lead to a spongy brake pedal feel and reduced braking efficiency.

Inside the master cylinder, two pistons work in tandem to create the necessary hydraulic pressure. The primary piston is closest to the brake pedal and is directly actuated by the pedal’s movement. As the brake pedal is pressed, this piston moves forward, displacing brake fluid and creating pressure in the primary circuit. The secondary piston, located further inside the cylinder, is moved by the pressure created by the primary piston. This dual-piston design is what allows for the separation of brake circuits, enhancing safety.

Seals play a critical role in the master cylinder’s operation. High-quality rubber seals are used to prevent fluid leakage and maintain pressure within the system. These seals are designed to withstand the high pressures and temperature variations encountered during braking. Over time, these seals can wear out, potentially leading to brake fluid leaks or a loss of pressure in the system.

When the brake pedal is released, return springs inside the master cylinder push the pistons back to their rest position. This action draws brake fluid from the reservoir back into the cylinder bores, readying the system for the next brake application. The quick return of the pistons is essential for maintaining proper pedal feel and ensuring that the brakes release promptly when the pedal is let go.

The master cylinder connects to the rest of the braking system via brake lines. These lines carry the pressurized brake fluid to the wheel cylinders or calipers. In a dual-circuit system, separate lines run to the front and rear brakes, providing redundancy in case of a failure in one circuit. The design and routing of these lines are carefully engineered to withstand the high pressures involved in braking and to resist damage from road debris and environmental factors.

Types of Master Cylinders and Their Applications

Master cylinders come in various types, each designed for specific vehicle applications and braking system configurations. The two main categories are single-circuit and dual-circuit master cylinders, with the latter being the standard in modern vehicles due to safety regulations.

Single-circuit master cylinders, found in older vehicles, use a single piston to pressurize brake fluid for all wheels. While simpler in design, they pose a significant safety risk because a failure in any part of the system could result in a complete loss of braking power. For this reason, single-circuit systems are no longer used in modern passenger vehicles.

Dual-circuit master cylinders, introduced in the 1960s, significantly improved brake system safety. They feature two separate circuits, typically configured in one of two ways:

- Front/Rear Split: One circuit controls the front brakes, while the other controls the rear brakes.

- Diagonal Split: One circuit controls the right front and left rear brakes, while the other controls the left front and right rear brakes.

The diagonal split configuration is particularly effective because it ensures that braking force is applied to both sides of the vehicle even if one circuit fails, helping to maintain directional stability during emergency braking.

Some high-performance vehicles and heavy-duty applications use tandem master cylinders. These feature two separate master cylinders mounted in-line, each controlling its own brake circuit. This design allows for even greater redundancy and can provide more precise brake balance control in racing applications.

For vehicles with anti-lock braking systems (ABS), the master cylinder works in conjunction with the ABS hydraulic control unit. In these systems, the master cylinder provides the initial hydraulic pressure, which is then modulated by the ABS unit to prevent wheel lockup during hard braking or on slippery surfaces.

Brake boosters are often used in conjunction with master cylinders to reduce the effort required to press the brake pedal. There are two main types of brake boosters:

- Vacuum Boosters: Use engine vacuum to multiply the force applied to the brake pedal.

- Hydraulic Boosters: Use hydraulic pressure from the power steering pump to assist braking.

The choice between these booster types depends on the vehicle’s design and the available power sources. Electric and hybrid vehicles, which may not have consistent engine vacuum, often use electric brake boosters or hydraulic systems.

Maintenance and Troubleshooting of Master Cylinder Systems

Proper maintenance of the master cylinder is crucial for ensuring the safety and reliability of a vehicle’s braking system. Regular inspections and timely repairs can prevent many common issues associated with master cylinder failure. Here are some key aspects of master cylinder maintenance and troubleshooting:

Fluid Level and Quality: One of the most important maintenance tasks is regularly checking the brake fluid level and quality. Low fluid levels can indicate a leak in the system or worn brake pads. The fluid should be clear and free of contaminants. If the fluid appears dark or has particles in it, it’s time for a brake fluid flush. Most manufacturers recommend changing the brake fluid every 2-3 years to prevent moisture buildup and maintain optimal performance.

Seal Integrity: The seals within the master cylinder are critical for maintaining pressure. Over time, these seals can degrade, leading to internal or external leaks. Signs of failing seals include:

- A sinking brake pedal

- Visible fluid leaks around the master cylinder

- Decreased braking performance

If any of these symptoms are noticed, immediate inspection and potential replacement of the master cylinder may be necessary.

Brake Line Inspection: While not part of the master cylinder itself, the condition of brake lines directly affects its performance. Regular inspections should check for:

- Corrosion or damage to metal brake lines

- Cracks or swelling in flexible brake hoses

- Secure fittings and connections

Any signs of wear or damage should be addressed promptly to prevent brake failure.

Bleeding the System: Air in the brake lines can significantly reduce braking efficiency. If the brake pedal feels spongy or if work has been done on the braking system, bleeding the brakes is necessary. This process removes air bubbles from the brake lines, ensuring that only fluid is present to transmit force from the master cylinder to the wheel cylinders or calipers.

Booster Function: For vehicles with brake boosters, proper operation is essential for easy pedal application. A faulty booster can lead to a hard brake pedal and reduced braking power. Testing the booster involves checking for proper vacuum or hydraulic pressure and ensuring the check valve is functioning correctly.

When troubleshooting master cylinder issues, it’s important to consider the entire braking system. Problems that may seem related to the master cylinder could actually be caused by other components. For example, a brake fluid leak from a wheel cylinder might cause symptoms similar to a failing master cylinder.

If a problem with the master cylinder is suspected, a thorough inspection should include:

- Checking for visible leaks around the master cylinder and brake lines

- Testing the brake pedal feel for firmness and consistency

- Inspecting the brake fluid for proper level and quality

- Verifying that the brake lights function correctly, as the brake light switch is often located near the master cylinder

In cases where the master cylinder needs replacement, it’s often recommended to replace the brake booster at the same time, especially in older vehicles. This ensures that the entire braking system is in good condition and operating at peak efficiency.

FAQs About What Master Cylinder Brake System Does

- How often should brake fluid be changed in a master cylinder?

Brake fluid should typically be changed every 2-3 years or as recommended by the vehicle manufacturer. - Can a faulty master cylinder cause uneven braking?

Yes, a failing master cylinder can lead to uneven pressure distribution, causing uneven braking across wheels. - What causes a spongy brake pedal?

A spongy brake pedal is often caused by air in the brake lines or a failing master cylinder. - How long does a master cylinder typically last?

A master cylinder can last 60,000 to 100,000 miles, but lifespan varies based on driving conditions and maintenance. - Is it safe to drive with a leaking master cylinder?

No, driving with a leaking master cylinder is unsafe as it can lead to brake failure and should be repaired immediately.