The master cylinder is a crucial component of a vehicle’s braking system, responsible for converting the mechanical force applied to the brake pedal into hydraulic pressure. This pressure is then distributed to the brake calipers or wheel cylinders at each wheel, enabling the vehicle to slow down or stop. Master cylinder brakes play a vital role in ensuring safe and efficient braking performance, making them an essential part of any vehicle’s safety system.

When a driver presses the brake pedal, the master cylinder’s internal pistons move, displacing brake fluid and creating hydraulic pressure. This pressure is then transmitted through brake lines to the individual wheel brakes, activating the braking mechanism. The master cylinder’s design allows for consistent and reliable brake operation, ensuring that drivers can safely control their vehicles in various driving conditions.

| Component | Function |

|---|---|

| Pistons | Displace brake fluid to create pressure |

| Reservoir | Stores brake fluid for system operation |

| Seals | Prevent fluid leakage and maintain pressure |

| Brake lines | Transmit hydraulic pressure to wheel brakes |

Types of Master Cylinder Brakes

There are two main types of master cylinder brakes: single circuit and tandem (dual circuit) systems. Each type has its own advantages and applications, catering to different vehicle designs and safety requirements.

Single circuit master cylinders were commonly used in older vehicles. They feature a single piston and fluid reservoir, controlling all four wheel brakes through a single hydraulic circuit. While simpler in design, these systems pose a significant safety risk. If a leak occurs anywhere in the brake system, it can result in a complete loss of braking power, potentially leading to dangerous situations on the road.

Tandem master cylinders, also known as dual circuit systems, are the standard in modern vehicles. They incorporate two separate pistons and fluid chambers within a single cylinder body. This design creates two independent hydraulic circuits, typically split diagonally (front-left/rear-right and front-right/rear-left) or front/rear. The primary advantage of tandem master cylinders is their fail-safe capability. If one circuit fails due to a leak or other issue, the other circuit remains operational, providing partial braking power and significantly enhancing vehicle safety.

The introduction of tandem master cylinders has greatly improved brake system reliability and safety. In the event of a failure in one circuit, drivers can still maintain some level of braking control, allowing them to safely bring their vehicle to a stop. This redundancy is a critical safety feature that has become standard in automotive design.

Another important aspect of master cylinder design is the bore size. The diameter of the master cylinder bore affects the amount of fluid displaced and the resulting hydraulic pressure. A smaller bore size generally produces higher pressure but requires more pedal effort, while a larger bore size creates lower pressure but offers easier pedal operation. Engineers must carefully balance these factors to achieve optimal braking performance and pedal feel for each specific vehicle application.

Master Cylinder Components and Operation

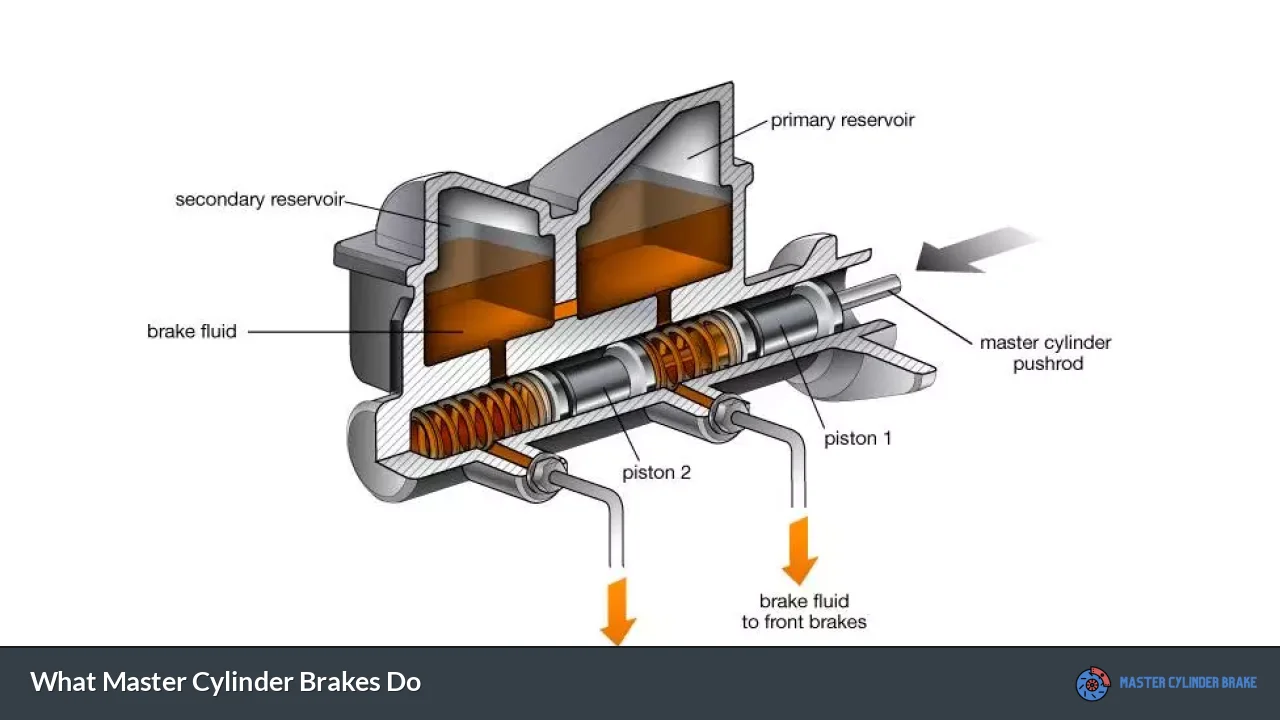

Understanding the components and operation of master cylinder brakes is essential for appreciating their role in vehicle safety. The main components of a master cylinder include the cylinder body, pistons, seals, springs, and fluid reservoir.

The cylinder body is typically made of cast iron or aluminum and houses the internal components. It’s designed to withstand high pressures and resist corrosion from brake fluid. The pistons, usually made of steel or aluminum, move within the cylinder bore to displace brake fluid. High-quality seals, often made of rubber or synthetic materials, are crucial for maintaining pressure and preventing fluid leaks.

When the brake pedal is pressed, it activates a push rod connected to the master cylinder. This action moves the primary piston forward, displacing brake fluid and creating pressure in the first circuit. In a tandem system, the movement of the primary piston also causes the secondary piston to move, activating the second circuit. As the pistons move, they compress springs within the cylinder. These springs help return the pistons to their rest position when the brake pedal is released, allowing brake fluid to flow back into the master cylinder reservoir.

The fluid reservoir, typically mounted on top of the master cylinder, stores excess brake fluid and compensates for fluid level changes due to pad wear and temperature fluctuations. It’s essential to maintain the proper fluid level in the reservoir to ensure optimal brake performance and prevent air from entering the system.

One critical feature of modern master cylinders is the quick take-up design. This feature allows for faster initial brake application by reducing the distance the piston must travel before building pressure. It’s particularly useful in vehicles with disc brakes, which require a larger volume of fluid displacement compared to drum brakes.

Maintenance and Troubleshooting

Proper maintenance of the master cylinder is crucial for ensuring reliable brake performance and vehicle safety. Regular inspection and servicing can help prevent issues and extend the lifespan of the braking system. Here are some key maintenance tasks and troubleshooting tips:

- Fluid level checks: Regularly inspect the brake fluid level in the reservoir. Low fluid levels can indicate brake pad wear or potential leaks in the system. Always use the type of brake fluid specified by the vehicle manufacturer.

- Fluid quality: Brake fluid is hygroscopic, meaning it absorbs moisture from the air over time. This can lead to reduced boiling point and potential brake fade. Most manufacturers recommend changing brake fluid every 2-3 years.

- Seal inspection: Check for signs of fluid leakage around the master cylinder, which could indicate worn or damaged seals. Replace seals or the entire master cylinder if leaks are detected.

- Pedal feel: Pay attention to changes in brake pedal feel. A spongy or soft pedal could indicate air in the system, while a hard pedal might suggest a problem with the brake booster or hydraulic system.

- Bleeding the system: If air enters the brake system, it must be bled to remove the air and restore proper function. This typically involves opening bleeder valves at each wheel while pumping the brake pedal.

- Corrosion prevention: Keep the area around the master cylinder clean and dry to prevent corrosion, which can lead to seal damage and fluid contamination.

If you notice any unusual brake behavior, such as reduced stopping power, unusual noises, or warning lights on the dashboard, it’s important to have the system inspected by a qualified mechanic. Prompt attention to brake issues can prevent more serious problems and ensure your vehicle remains safe to operate.

When replacing a master cylinder, it’s crucial to select the correct type for your vehicle. Factors to consider include the bore size, reservoir capacity, and compatibility with your vehicle’s brake system design. Always use high-quality replacement parts and follow proper installation procedures to ensure optimal performance and safety.

FAQs About Master Cylinder Brakes

- How often should brake fluid be changed in a master cylinder?

Most manufacturers recommend changing brake fluid every 2-3 years to maintain optimal performance and safety. - Can a faulty master cylinder cause brake failure?

Yes, a severely damaged or leaking master cylinder can lead to partial or complete brake failure, compromising vehicle safety. - What are signs of a failing master cylinder?

Common signs include a spongy brake pedal, fluid leaks, uneven braking, and warning lights on the dashboard. - Is it possible to repair a master cylinder or should it be replaced?

While some master cylinders can be rebuilt, replacement is often recommended for safety and reliability reasons. - How does ABS affect master cylinder operation?

ABS systems work in conjunction with the master cylinder, rapidly modulating brake pressure to prevent wheel lockup during hard braking.