The master cylinder is a critical component of your vehicle’s braking system, responsible for converting the force applied to the brake pedal into hydraulic pressure that activates the brakes. When this vital part malfunctions, it can lead to serious safety issues and compromised braking performance. Recognizing the signs of a failing master cylinder is crucial for maintaining your vehicle’s safety and preventing potential accidents on the road.

A bad master cylinder can manifest in various ways, from subtle changes in pedal feel to more obvious symptoms like fluid leaks or complete brake failure. Understanding these indicators can help you identify problems early and take appropriate action before they escalate into more serious issues. Regular maintenance and prompt attention to any brake-related concerns are essential for ensuring your vehicle’s braking system remains in optimal condition.

Let’s explore the key symptoms, causes, and solutions related to a faulty master cylinder, providing you with the knowledge to diagnose and address this critical brake system component effectively.

| Symptom | Possible Cause |

|---|---|

| Spongy brake pedal | Internal seal failure |

| Brake fluid leaks | External seal deterioration |

| Uneven braking | Partial system failure |

| Warning light activation | Low fluid level or pressure loss |

Symptoms of a Bad Master Cylinder

Recognizing the signs of a failing master cylinder is crucial for maintaining your vehicle’s safety. Several key indicators can alert you to potential issues with this critical component. One of the most common symptoms is a spongy or soft brake pedal. If you notice that your brake pedal feels less firm than usual or sinks to the floor with little resistance, it could indicate a problem with the master cylinder’s internal seals.

Another telltale sign is brake fluid leaks. You might notice a puddle of clear to light brown fluid beneath your vehicle, typically near the driver’s side firewall. This leakage can lead to a low brake fluid level, which in turn can trigger the brake warning light on your dashboard. It’s important to note that a consistently low brake fluid level, even without visible leaks, can indicate internal master cylinder issues.

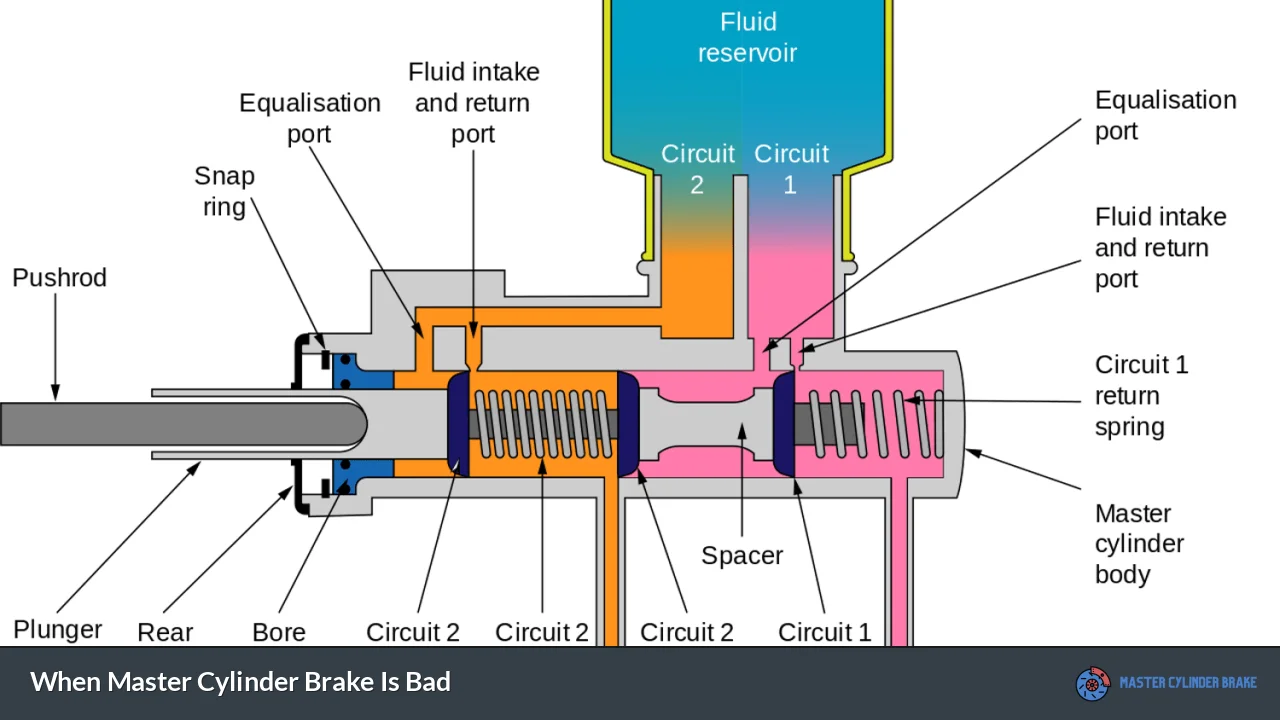

Uneven braking is another symptom to watch for. If you feel that your vehicle pulls to one side when braking or that the braking force is inconsistent, it could be due to a partial failure of the master cylinder. This occurs when one side of the dual-chamber master cylinder fails, affecting only half of the braking system.

In some cases, you might experience a complete loss of brake pedal pressure. This alarming symptom occurs when the master cylinder fails entirely, resulting in no resistance when pressing the brake pedal. If you encounter this situation, it’s crucial to stop driving immediately and seek professional assistance.

Contaminated brake fluid can also indicate master cylinder problems. If you notice that your brake fluid has become dark or has debris floating in it, it could be a sign of internal master cylinder deterioration. Regular brake fluid checks can help you catch this issue early.

Lastly, pay attention to any changes in brake pedal behavior. If the pedal gradually sinks to the floor while holding pressure, or if you need to pump the brakes to build pressure, these could be signs of a failing master cylinder. These symptoms often worsen over time, so it’s essential to address them promptly to prevent more severe braking issues.

Causes of Master Cylinder Failure

Understanding the causes of master cylinder failure can help you prevent issues and recognize potential problems early. One of the primary causes is normal wear and tear. Over time, the internal seals and components of the master cylinder can degrade, leading to leaks and reduced performance. This wear is accelerated by factors such as high mileage, frequent use, and exposure to extreme temperatures.

Contaminated brake fluid is another significant factor contributing to master cylinder failure. Brake fluid is hygroscopic, meaning it absorbs moisture from the air. This moisture can lead to corrosion inside the master cylinder and throughout the brake system. Regular brake fluid changes are crucial to prevent this type of damage.

Physical damage to the master cylinder can also occur, particularly in the event of a collision or impact to the engine compartment. Even minor damage can compromise the cylinder’s integrity, leading to leaks or internal failures. It’s important to inspect the master cylinder after any significant impact to the vehicle.

Manufacturing defects, while rare, can sometimes be the cause of premature master cylinder failure. These defects might not be immediately apparent and can manifest over time as the component is subjected to normal use and stress.

Improper installation or maintenance can also lead to master cylinder issues. If the master cylinder is not correctly installed, or if incompatible brake fluid is used, it can cause damage and premature failure. Always ensure that brake work is performed by qualified professionals using the correct parts and fluids.

Environmental factors play a role as well. Exposure to road salt, debris, and extreme temperatures can accelerate the deterioration of the master cylinder’s external components. Vehicles in harsh climates or those frequently driven in challenging conditions may experience master cylinder issues more frequently.

Overheating of the brake system can indirectly affect the master cylinder. Excessive heat generated by frequent hard braking or dragging brakes can cause the brake fluid to boil, leading to vapor lock and reduced braking efficiency. This can put additional stress on the master cylinder.

Lastly, lack of use can paradoxically cause problems. If a vehicle sits unused for extended periods, seals can dry out and stick, leading to leaks or failure when the vehicle is put back into service. Regular use helps keep the seals pliable and functioning correctly.

Diagnosing a Bad Master Cylinder

Accurately diagnosing a bad master cylinder is crucial for ensuring your vehicle’s safety and preventing unnecessary repairs. The first step in diagnosis is a visual inspection. Check for any signs of brake fluid leaks around the master cylinder, brake lines, and on the ground beneath your parked vehicle. Look for wet spots or stains on the master cylinder itself and the surrounding area in the engine compartment.

Next, check the brake fluid level in the reservoir. A consistently low fluid level, even after refilling, can indicate a leak in the master cylinder or elsewhere in the brake system. Also, inspect the quality of the brake fluid. If it appears dark or contaminated, it may be a sign of internal master cylinder deterioration.

Test the brake pedal feel. With the engine off, press the brake pedal several times to deplete any vacuum in the brake booster. Then, with steady pressure on the pedal, start the engine. The pedal should sink slightly and then hold firm. If it continues to sink, this could indicate a problem with the master cylinder.

Perform a stationary brake test. With the engine running, apply steady pressure to the brake pedal for about 10-15 seconds. If the pedal slowly sinks to the floor, it’s a strong indication of a master cylinder leak. However, be cautious with this test, as it can be dangerous if the brakes fail completely.

Check for uneven braking. If possible, test drive the vehicle in a safe area. Pay attention to any pulling to one side during braking or inconsistent brake performance. This could indicate a partial failure of the master cylinder, affecting only one brake circuit.

Use a brake pressure gauge to check for proper pressure in the brake lines. This specialized tool can help identify if the master cylinder is generating adequate pressure. Low or inconsistent pressure readings can point to master cylinder issues.

Inspect the brake warning light on your dashboard. If it stays on or comes on intermittently, it could indicate low brake fluid levels or a problem with the brake pressure differential switch, both of which can be related to master cylinder issues.

For a more definitive diagnosis, consider a professional inspection. A certified mechanic can perform more advanced tests, including isolating the master cylinder from the rest of the brake system to check for internal leaks. They may also use specialized diagnostic equipment to assess the entire brake system’s performance.

Remember, while these diagnostic steps can help identify a bad master cylinder, brake system issues can be complex and interrelated. If you’re unsure about any aspect of diagnosis or repair, it’s always best to consult with a professional mechanic to ensure your vehicle’s safety.

Replacing a Faulty Master Cylinder

Replacing a faulty master cylinder is a critical task that requires careful attention to detail and proper safety precautions. While it’s possible for experienced DIY mechanics to perform this repair, many vehicle owners choose to have it done by a professional due to the complexity and safety-critical nature of the brake system.

The first step in replacing a master cylinder is to gather the necessary tools and parts. You’ll need a new master cylinder that matches your vehicle’s specifications, brake fluid, wrenches, pliers, and potentially a brake bleeding kit. Always consult your vehicle’s service manual for specific instructions and torque specifications.

Before beginning the replacement, safety is paramount. Ensure the vehicle is parked on a level surface, the engine is off, and the parking brake is engaged. Disconnect the negative terminal of the battery to prevent any electrical issues during the repair.

Start by locating the master cylinder in the engine compartment. It’s typically mounted on the brake booster on the driver’s side firewall. Before removing any components, take a picture or make a diagram of the brake line connections to ensure proper reassembly.

Carefully disconnect the brake lines from the master cylinder. Be prepared for some brake fluid to leak out. Use a line wrench to avoid rounding off the fittings. Cap the brake lines to prevent contamination and excessive fluid loss.

Next, remove the master cylinder mounting bolts. These usually connect the master cylinder to the brake booster. Once the bolts are removed, carefully pull the master cylinder away from the booster. Be cautious of any remaining brake fluid in the cylinder.

Before installing the new master cylinder, it’s crucial to bench bleed it. This process removes air from the cylinder before installation, ensuring proper operation. Follow the manufacturer’s instructions for bench bleeding, as the process can vary.

Install the new master cylinder by reversing the removal process. Ensure all connections are tight and properly aligned. Refill the brake fluid reservoir with the correct type of brake fluid for your vehicle.

After installation, you’ll need to bleed the entire brake system to remove any air that may have entered during the replacement process. This typically involves bleeding each brake caliper or wheel cylinder, starting with the one farthest from the master cylinder.

Finally, test the brakes thoroughly before driving the vehicle on public roads. Check for proper pedal feel, ensure there are no leaks, and verify that the brake warning light is not illuminated. A test drive in a safe area can help confirm that the brakes are functioning correctly.

Remember, if you’re not comfortable performing this repair yourself, it’s best to leave it to a professional. Proper installation and bleeding of the master cylinder are crucial for ensuring your vehicle’s braking system functions safely and effectively.

FAQs About When Master Cylinder Brake Is Bad

- How long does a master cylinder typically last?

A well-maintained master cylinder can last 60,000 to 100,000 miles, but lifespan varies based on driving conditions and maintenance. - Can I drive with a bad master cylinder?

It’s not safe to drive with a faulty master cylinder as it can lead to complete brake failure. Immediate repair is necessary. - How much does it cost to replace a master cylinder?

Replacement costs typically range from $200 to $500, depending on the vehicle make and model and labor rates. - Can a master cylinder be repaired instead of replaced?

While some master cylinders can be rebuilt, replacement is often recommended for safety and reliability reasons. - How often should brake fluid be changed to prevent master cylinder issues?

Most manufacturers recommend changing brake fluid every 2 years or 30,000 miles to prevent contamination and system damage.