The master cylinder is a critical component of your vehicle’s braking system, responsible for converting the force you apply to the brake pedal into hydraulic pressure. This pressure then activates the brake calipers or wheel cylinders, bringing your vehicle to a stop. When the master cylinder starts to fail, it can lead to serious safety issues and compromised braking performance. Recognizing the signs of a failing master cylinder is crucial for maintaining your vehicle’s safety and preventing potential accidents on the road.

A faulty master cylinder can manifest in various ways, from subtle changes in pedal feel to more obvious symptoms like fluid leaks or complete brake failure. Understanding these symptoms can help you identify problems early and take appropriate action before they escalate into more serious issues. Regular maintenance and prompt attention to any brake-related concerns are essential for ensuring your vehicle’s braking system remains in optimal condition.

| Symptom | Possible Cause |

|---|---|

| Spongy brake pedal | Internal seal failure |

| Brake fluid leaks | External seal deterioration |

| Uneven braking | Partial system failure |

| Warning light activation | Low fluid level or pressure loss |

Common Symptoms of a Bad Master Cylinder

Identifying the signs of a failing master cylinder is crucial for maintaining your vehicle’s safety. Several symptoms can indicate that your master cylinder is experiencing problems:

Spongy or soft brake pedal: One of the most common signs of a failing master cylinder is a brake pedal that feels soft, spongy, or gradually sinks to the floor when pressure is applied. This occurs when air enters the brake lines or when there’s a loss of hydraulic pressure due to internal seal failure. The pedal may feel normal initially but gradually sink as you hold it down, indicating a slow leak within the master cylinder.

Brake fluid leaks: Visible brake fluid leaks are a clear indicator of master cylinder problems. You might notice puddles of clear to light brown fluid beneath your vehicle, typically near the driver’s side firewall where the master cylinder is located. These leaks can occur due to worn external seals or damage to the master cylinder housing. It’s important to address leaks promptly, as low brake fluid levels can lead to complete brake failure.

Contaminated brake fluid: If you notice that your brake fluid has turned dark or has visible contaminants, it could be a sign of internal master cylinder problems. As the internal seals wear down, they can contaminate the brake fluid with rubber particles or allow moisture to enter the system. This contamination can lead to reduced braking performance and accelerated wear of other brake components.

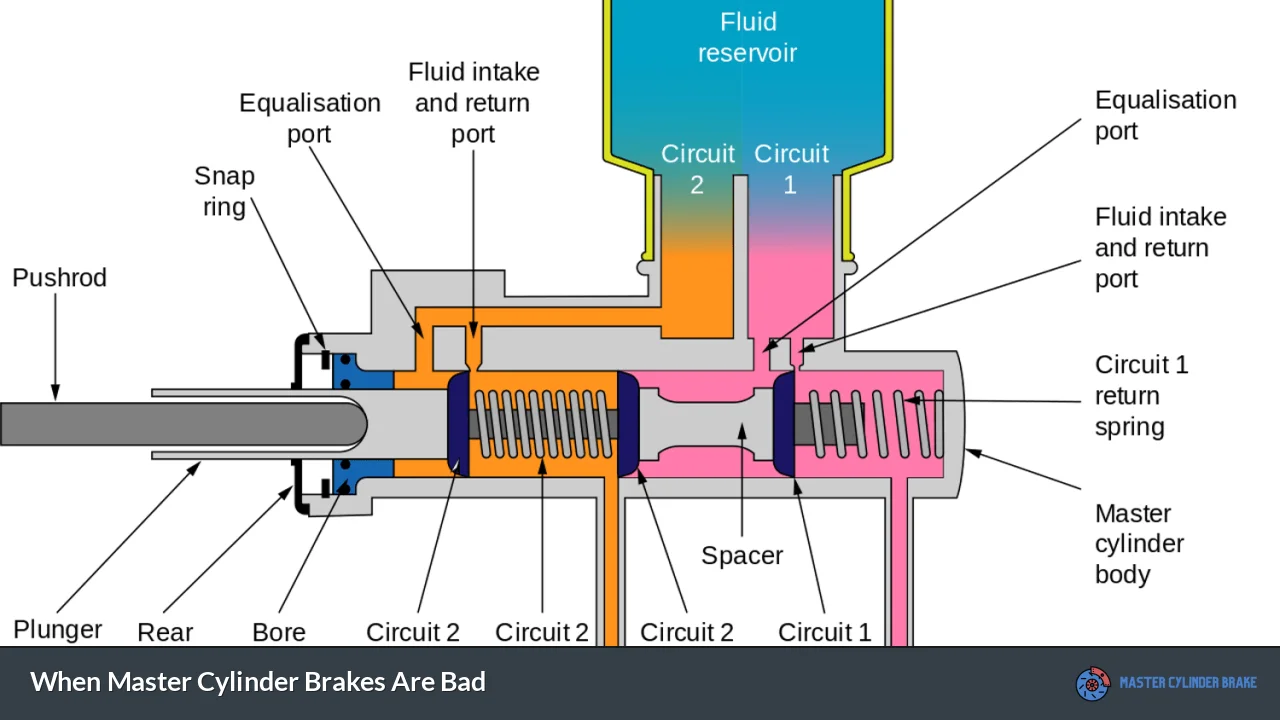

Uneven braking: A failing master cylinder may cause uneven braking, where one side of the vehicle brakes more effectively than the other. This occurs when one circuit of the dual-circuit master cylinder fails, leading to reduced pressure on one side of the braking system. You might notice your vehicle pulling to one side when braking or that more pedal pressure is required to achieve the same stopping power.

Warning light activation: Modern vehicles are equipped with brake system warning lights that can indicate various issues, including master cylinder problems. If your brake warning light illuminates on the dashboard, it could be due to low brake fluid levels caused by a leak in the master cylinder or a loss of pressure in one of the brake circuits. Never ignore a brake warning light, as it can indicate a serious safety issue.

Causes of Master Cylinder Failure

Understanding the causes of master cylinder failure can help you prevent problems and recognize when maintenance is necessary. Several factors can contribute to the deterioration of your vehicle’s master cylinder:

Normal wear and tear: Like all mechanical components, master cylinders are subject to wear over time. The internal seals and pistons can degrade with repeated use, leading to leaks and reduced performance. The rate of wear can vary depending on driving conditions, frequency of use, and the quality of the component.

Contaminated brake fluid: Brake fluid is hygroscopic, meaning it absorbs moisture from the air. Over time, this absorbed moisture can lead to corrosion within the master cylinder and other brake system components. Additionally, if the brake fluid becomes contaminated with dirt or debris, it can cause accelerated wear of the internal seals and pistons.

Heat exposure: The master cylinder is typically located near the engine, exposing it to high temperatures. Prolonged exposure to heat can cause the brake fluid to break down and the seals to deteriorate more quickly. This is particularly problematic in vehicles that are frequently used for towing or in stop-and-go traffic, where brake temperatures can rise significantly.

Lack of maintenance: Regular brake system maintenance, including fluid changes and inspections, is crucial for the longevity of the master cylinder. Neglecting these maintenance tasks can lead to premature failure due to contaminated fluid or undetected wear.

Manufacturing defects: While less common, manufacturing defects can sometimes lead to premature master cylinder failure. This could include issues with material quality, assembly problems, or design flaws that become apparent over time.

Improper installation: If a master cylinder is not installed correctly, it can lead to problems such as misalignment, improper sealing, or damage to the component. This is why it’s crucial to have brake work performed by qualified professionals.

Diagnosing Master Cylinder Problems

Accurately diagnosing master cylinder problems is essential for determining the appropriate course of action. While some symptoms may be obvious, others can be subtle and require careful inspection. Here are some steps to diagnose master cylinder issues:

Visual inspection: Begin by visually inspecting the master cylinder and surrounding area for signs of fluid leaks. Look for wet spots or stains on the master cylinder itself, as well as on the firewall and nearby components. Check the brake fluid reservoir level and condition of the fluid. Low fluid levels or contaminated fluid can indicate master cylinder problems.

Pedal feel test: With the engine off, press the brake pedal several times to deplete any vacuum in the brake booster. Then, apply steady pressure to the pedal. If the pedal gradually sinks to the floor, it could indicate a leak in the master cylinder. Next, start the engine and repeat the test. The pedal should feel firm and maintain its position. If it doesn’t, there may be an issue with the master cylinder or brake booster.

Pressure testing: A professional mechanic can perform a pressure test on the brake system to check for leaks and proper pressure distribution. This involves using specialized equipment to measure the hydraulic pressure at various points in the system, which can help identify if the master cylinder is functioning correctly.

Brake bleeding: If air is suspected in the brake lines, bleeding the brakes can help determine if the issue is with the master cylinder or elsewhere in the system. If air continues to enter the system after proper bleeding, it may indicate a problem with the master cylinder’s internal seals.

Warning light diagnosis: If the brake warning light is illuminated, use an OBD-II scanner to read any diagnostic trouble codes. These codes can provide valuable information about the nature of the problem, including issues related to the master cylinder or brake pressure.

Brake performance test: Test the vehicle’s braking performance in a safe area. Pay attention to any pulling to one side, unusual noises, or changes in pedal feel during braking. Uneven braking or a significant increase in stopping distance can indicate master cylinder issues.

Replacing a Faulty Master Cylinder

When a master cylinder is diagnosed as faulty, replacement is often the most reliable solution. While some minor issues can be repaired, such as external seal replacement, internal problems typically require a complete replacement of the unit. Here’s an overview of the replacement process:

Safety precautions: Before beginning any work on the brake system, ensure the vehicle is safely parked on a level surface with the wheels chocked. Wear appropriate safety gear, including gloves and eye protection, as brake fluid can be harmful to skin and eyes.

Fluid drainage: Start by removing as much brake fluid as possible from the reservoir using a clean syringe or turkey baster. This will minimize spillage during the replacement process. Dispose of old brake fluid properly, as it is considered hazardous waste.

Disconnecting brake lines: Carefully disconnect the brake lines from the master cylinder. Use a line wrench to avoid rounding off the fittings. Have a container ready to catch any remaining fluid that may drain out. Cap the lines to prevent contamination and further fluid loss.

Removing the old master cylinder: Disconnect any electrical connections to the brake fluid level sensor if present. Remove the mounting nuts or bolts that secure the master cylinder to the brake booster or firewall. Carefully withdraw the master cylinder, being mindful of any remaining fluid.

Installing the new master cylinder: Before installation, bench bleed the new master cylinder to remove any air from its internal chambers. This process involves filling the reservoir and using a special kit to cycle fluid through the cylinder ports. Once bled, carefully install the new master cylinder, ensuring proper alignment with the brake booster pushrod.

Reconnecting and bleeding: Reconnect the brake lines, taking care not to cross-thread or overtighten the fittings. Refill the reservoir with fresh brake fluid of the correct type for your vehicle. Bleed the entire brake system to remove any air that may have entered during the replacement process.

Testing: After installation and bleeding, perform a thorough test of the brake system. Check for leaks around all connections and verify proper pedal feel and braking performance. Take the vehicle for a test drive in a safe area to ensure the brakes are functioning correctly.

FAQs About When Master Cylinder Brakes Are Bad

- How long does a master cylinder typically last?

A master cylinder can last 60,000 to 200,000 miles, depending on driving conditions and maintenance. - Can you drive with a bad master cylinder?

It’s not safe to drive with a bad master cylinder as it can lead to complete brake failure. - How much does it cost to replace a master cylinder?

Replacement costs typically range from $200 to $500, including parts and labor. - Can a master cylinder be repaired instead of replaced?

Minor external leaks can sometimes be repaired, but internal issues usually require full replacement. - How often should brake fluid be changed?

Most manufacturers recommend changing brake fluid every 2 years or 30,000 miles for optimal performance.