The master cylinder is a crucial component of your vehicle’s braking system, responsible for converting the force applied to the brake pedal into hydraulic pressure that activates the brakes. Over time, this vital part can wear out or develop issues that compromise its effectiveness, potentially putting your safety at risk. Recognizing the signs that indicate your master cylinder needs replacement is essential for maintaining optimal braking performance and ensuring your vehicle’s safety on the road.

Understanding when to replace your master cylinder can save you from unexpected brake failures and costly repairs down the line. This article will guide you through the key indicators that suggest it’s time for a replacement, the importance of timely action, and what to expect during the replacement process. We’ll also provide insights into the typical lifespan of a master cylinder and tips for maintaining this critical component to extend its longevity.

| Symptom | Potential Cause |

|---|---|

| Spongy brake pedal | Air in brake lines or failing master cylinder |

| Brake warning light on | Low brake fluid or master cylinder issues |

| Fluid leaks | Damaged seals in master cylinder |

| Inconsistent braking | Internal master cylinder failure |

Signs Your Master Cylinder Needs Replacement

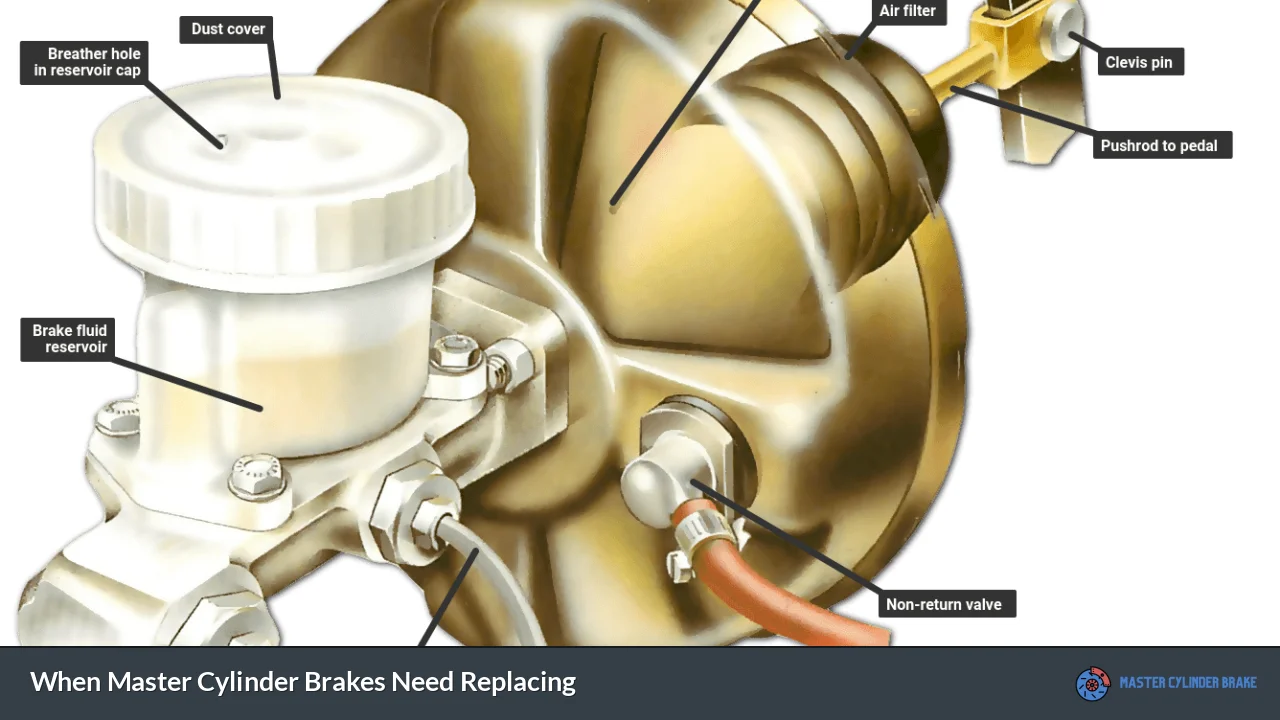

Recognizing the symptoms of a failing master cylinder is crucial for maintaining your vehicle’s safety. Several key indicators suggest it’s time to consider replacing this vital component. One of the most common signs is a spongy or soft brake pedal. If you notice that your brake pedal feels less firm than usual or sinks to the floor when pressed, it could indicate air in the brake lines or a failing master cylinder. This symptom should never be ignored, as it can significantly compromise your ability to stop the vehicle effectively.

Another telltale sign is the presence of brake fluid leaks. If you notice a puddle of clear or slightly yellow fluid beneath your vehicle, particularly near the driver’s side firewall, it’s likely brake fluid leaking from a damaged master cylinder. Brake fluid leaks can quickly lead to a loss of hydraulic pressure, severely impacting your braking ability. Regular checks under your vehicle can help catch this issue early.

The illumination of the brake warning light on your dashboard is another critical indicator that shouldn’t be overlooked. While this light can signify various brake-related issues, including low brake fluid levels, it often points to problems with the master cylinder. Modern vehicles are equipped with sensors that detect changes in brake fluid pressure or levels, triggering the warning light when anomalies are detected.

Inconsistent braking performance is a serious symptom that may indicate master cylinder failure. If you experience situations where your vehicle pulls to one side when braking or the brake pedal’s responsiveness varies, it could be due to internal issues within the master cylinder. This inconsistency can make your vehicle unpredictable and dangerous to drive, necessitating immediate attention.

A contaminated brake fluid reservoir is another sign that your master cylinder may need replacement. Over time, the rubber seals within the master cylinder can deteriorate, allowing contaminants to enter the brake fluid. If you notice that the brake fluid in the reservoir looks dark, cloudy, or contains visible particles, it’s a strong indication that internal components of the master cylinder are breaking down.

The Importance of Timely Replacement

Addressing master cylinder issues promptly is crucial for maintaining your vehicle’s safety and preventing more extensive damage to the braking system. Delaying replacement when signs of failure are present can lead to catastrophic brake failure, potentially resulting in accidents, injuries, or worse. The master cylinder’s role in converting mechanical force to hydraulic pressure is fundamental to your vehicle’s ability to stop, making its proper function non-negotiable for safe driving.

Timely replacement also helps prevent cascading damage to other components of the braking system. A failing master cylinder can cause uneven pressure distribution, leading to premature wear on brake pads, rotors, and calipers. By addressing the issue early, you can avoid more extensive and costly repairs down the line. Additionally, a new master cylinder ensures that your vehicle’s braking performance is optimized, providing you with the confidence and control needed for safe driving in various conditions.

Another critical aspect of timely replacement is maintaining your vehicle’s value. Regular maintenance and prompt addressing of issues like a failing master cylinder can significantly impact your vehicle’s resale value. Potential buyers or dealerships often look for well-maintained vehicles with documented service histories, including critical safety component replacements.

It’s also worth noting that driving with a faulty master cylinder can void your vehicle’s warranty or insurance coverage in the event of an accident. Many policies require that vehicles be maintained in a roadworthy condition, which includes having a fully functional braking system. By replacing your master cylinder when needed, you ensure compliance with these requirements and protect yourself financially.

The Replacement Process

Replacing a master cylinder is a complex task that requires specific tools and expertise. While some experienced DIY enthusiasts might tackle this job, it’s generally recommended to have it performed by a qualified mechanic. The process typically involves several key steps, each crucial for ensuring the new master cylinder functions correctly and safely.

The first step in the replacement process is to drain the brake fluid from the system. This is done to prevent spillage and contamination during the replacement. Next, the mechanic will disconnect the brake lines from the old master cylinder, taking care to note their specific positions for correct reattachment later. The old master cylinder is then unbolted from the brake booster or firewall, depending on the vehicle’s design.

Before installing the new master cylinder, it must be bench bled. This crucial step removes air from the new unit, ensuring it will function properly once installed. The new master cylinder is then bolted into place, and the brake lines are carefully reconnected. After installation, the entire brake system must be bled to remove any remaining air. This process involves pumping the brake pedal while opening bleeder valves on each wheel in a specific sequence.

Finally, the system is refilled with fresh brake fluid, and the brakes are tested thoroughly to ensure proper operation. This includes checking for leaks, verifying pedal feel, and conducting road tests to confirm the braking system’s effectiveness under various conditions. The entire process can take several hours, depending on the vehicle model and any complications encountered.

Maintaining Your Master Cylinder

Proper maintenance can significantly extend the life of your master cylinder and help you avoid premature replacement. One of the most critical maintenance tasks is regularly checking and replacing brake fluid. Brake fluid is hygroscopic, meaning it absorbs moisture from the air over time. This moisture can lead to corrosion within the master cylinder and other brake components, potentially causing failure.

Most manufacturers recommend changing brake fluid every 2 years or 30,000 miles, whichever comes first. However, these intervals can vary based on driving conditions and vehicle specifications, so it’s essential to consult your owner’s manual for specific recommendations. During fluid changes, it’s also an opportunity to inspect the master cylinder and surrounding components for signs of wear or leakage.

Another crucial aspect of maintenance is addressing any brake-related issues promptly. If you notice changes in brake pedal feel, unusual noises when braking, or any of the symptoms mentioned earlier, have your vehicle inspected by a professional as soon as possible. Early detection and resolution of minor issues can prevent more significant problems and extend the life of your master cylinder.

Regularly inspecting brake lines and connections for signs of wear, corrosion, or damage is also important. While not directly part of the master cylinder, issues with these components can put additional stress on the master cylinder, potentially leading to premature failure. Keep an eye out for any signs of fluid leakage or deterioration in the rubber brake hoses.

Lastly, adhering to your vehicle’s overall maintenance schedule can indirectly benefit your master cylinder. Properly maintained suspension components, wheel alignments, and tire rotations ensure that your vehicle’s braking system operates under optimal conditions, reducing unnecessary stress on the master cylinder and other brake components.

FAQs About When Master Cylinder Brakes Need Replacing

- How often should a master cylinder be replaced?

Typically, master cylinders last 60,000 to 100,000 miles, but this varies based on driving conditions and maintenance. - Can I drive with a failing master cylinder?

It’s not safe to drive with a failing master cylinder as it significantly increases the risk of brake failure. - How much does it cost to replace a master cylinder?

Replacement costs typically range from $200 to $500, depending on the vehicle make and model. - Can a master cylinder be repaired instead of replaced?

In some cases, minor issues can be repaired, but full replacement is often safer and more reliable. - Will a bad master cylinder cause the brake pedal to go to the floor?

Yes, a failing master cylinder can cause the brake pedal to sink to the floor due to loss of hydraulic pressure.