The master cylinder and brake caliper are two crucial components of a vehicle’s braking system that work together to slow or stop a vehicle. The master cylinder converts the mechanical force from pressing the brake pedal into hydraulic pressure, while the brake caliper uses that pressure to clamp the brake pads against the rotor. Understanding how these parts function and interact is essential for proper vehicle maintenance and safety.

The master cylinder acts as the control center of the hydraulic brake system. When the driver presses the brake pedal, it pushes a piston inside the master cylinder. This action forces brake fluid through the brake lines to the calipers at each wheel. The calipers then use this hydraulic pressure to press the brake pads against the spinning rotor, creating friction that slows the vehicle.

Most modern vehicles use a dual circuit master cylinder design for safety. This means there are two separate fluid chambers and pistons controlling different sets of brakes. If one circuit fails, the other can still provide some braking power. The brake calipers are typically mounted over the brake rotors at each wheel, with one or more pistons inside to push the brake pads.

| Component | Primary Function |

|---|---|

| Master Cylinder | Converts pedal force to hydraulic pressure |

| Brake Caliper | Clamps brake pads against rotor |

Master Cylinder Operation

The master cylinder is the heart of the hydraulic brake system. Its main function is to generate the hydraulic pressure needed to operate the brakes when the driver presses the pedal. The master cylinder consists of a fluid reservoir, one or more pistons, and outlet ports that connect to the brake lines.

When the brake pedal is pressed, it pushes a rod connected to the primary piston inside the master cylinder. As this piston moves forward, it displaces brake fluid, creating pressure in the system. In a dual circuit design, the primary piston also pushes against a secondary piston, activating two separate brake circuits.

The fluid reservoir on top of the master cylinder holds extra brake fluid to accommodate for pad wear and thermal expansion. It also has ports that allow fluid to flow back into the reservoir when the brakes are released. This prevents pressure from building up in the lines when the brakes are not in use.

One critical component of the master cylinder is the brake booster. This device uses engine vacuum or an electric pump to multiply the force applied to the brake pedal. Without a booster, the driver would need to exert much more effort to generate sufficient braking force.

The size of the master cylinder bore is an important factor in brake system design. A larger bore diameter will move more fluid but require more pedal effort, while a smaller bore will increase hydraulic pressure but may result in a longer pedal travel. Engineers must balance these factors to achieve optimal brake feel and performance.

Brake Caliper Functionality

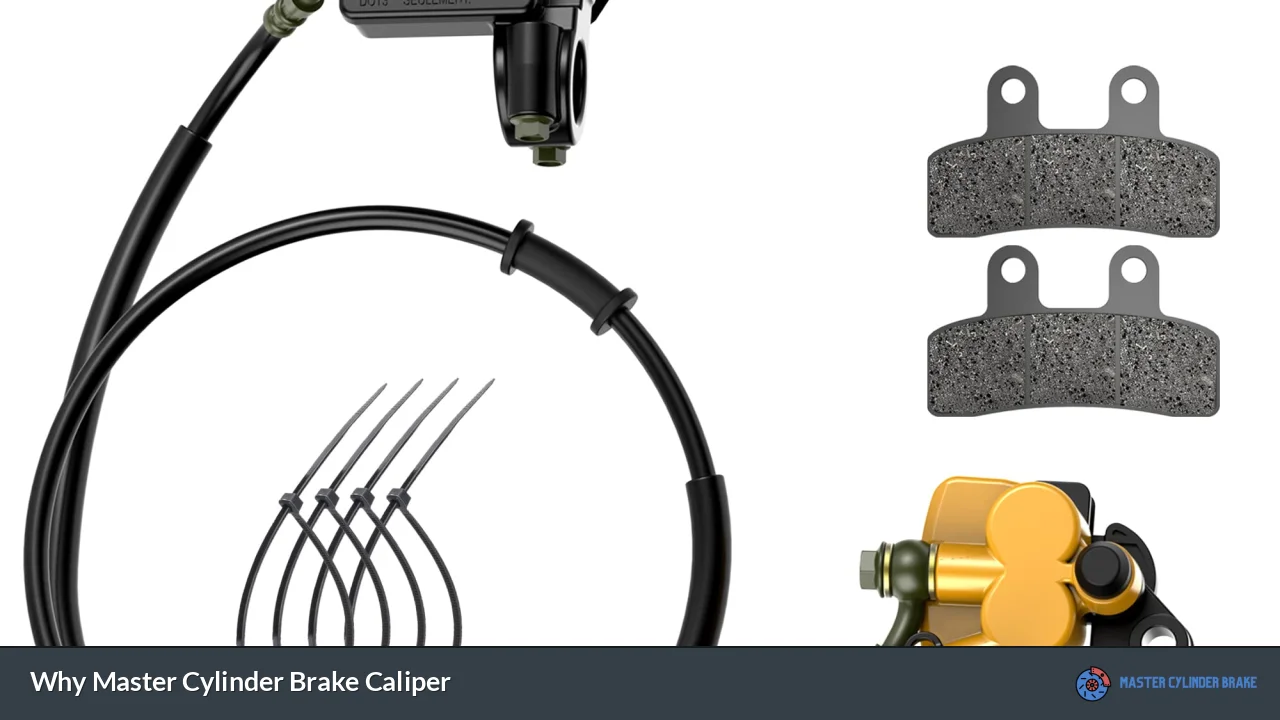

Brake calipers are the components that house the brake pads and pistons at each wheel. They use the hydraulic pressure from the master cylinder to clamp the pads against the rotor, creating the friction needed to slow or stop the vehicle. There are two main types of calipers: fixed and floating.

Fixed calipers have pistons on both sides of the rotor and don’t move relative to the rotor. They provide even pressure distribution and are often used in high-performance applications. Floating calipers, also called sliding calipers, have pistons on only one side and move slightly as the brakes are applied. They are more common in everyday vehicles due to their simpler design and lower cost.

When hydraulic pressure from the master cylinder reaches the caliper, it pushes against the piston(s) inside. The piston then presses the inner brake pad against the rotor. In a floating caliper, the entire caliper body slides slightly, bringing the outer pad into contact with the other side of the rotor.

The number and size of pistons in a caliper affect braking performance. More or larger pistons increase the clamping force but also require more fluid volume from the master cylinder. High-performance vehicles often use multi-piston calipers for improved braking power and heat dissipation.

Calipers also incorporate several other important components:

- Dust boots to protect the pistons from contamination

- Seals to prevent fluid leakage

- Slide pins (in floating calipers) to allow movement

- Bleed screws for removing air from the system

Proper maintenance of brake calipers is crucial for safe vehicle operation. This includes regular inspection for wear, corrosion, or fluid leaks, as well as cleaning and lubricating moving parts like slide pins.

Interaction Between Master Cylinder and Caliper

The master cylinder and brake calipers work together as a system to convert the driver’s pedal input into stopping power. This interaction relies on the principles of hydraulics to multiply force and transmit it efficiently throughout the brake system.

When the driver presses the brake pedal, the master cylinder creates hydraulic pressure in the brake lines. This pressure is equal in all parts of the system, following Pascal’s law. However, the force applied at each wheel can be different due to the size difference between the master cylinder piston and the caliper pistons.

The brake bias between front and rear wheels is an important consideration in system design. Most vehicles are designed with a front bias, meaning more braking force is applied to the front wheels. This is achieved through different piston sizes in the calipers and sometimes through proportioning valves in the hydraulic system.

One key aspect of the master cylinder-caliper relationship is fluid displacement. The master cylinder must displace enough fluid to move all the caliper pistons sufficiently. If the total volume of the calipers is too large relative to the master cylinder, it can result in a soft or spongy brake pedal feel.

The size relationship between the master cylinder and calipers also affects the mechanical advantage of the system. A smaller master cylinder bore relative to the total caliper piston area will increase the hydraulic force multiplication but require more pedal travel. Conversely, a larger master cylinder will provide a firmer pedal but may require more effort.

Brake engineers must carefully balance these factors to achieve the desired pedal feel, braking performance, and safety characteristics. This often involves extensive testing and fine-tuning of component sizes and ratios.

Maintenance and Troubleshooting

Proper maintenance of the master cylinder and brake calipers is essential for ensuring safe and effective vehicle braking. Regular inspections and timely repairs can prevent many common brake problems and extend the life of these critical components.

For the master cylinder, key maintenance tasks include:

- Checking the brake fluid level regularly

- Inspecting for leaks around the master cylinder and brake lines

- Replacing the brake fluid according to the manufacturer’s schedule

- Testing the brake pedal feel for signs of air in the system

Caliper maintenance typically involves:

- Inspecting brake pads for wear and replacing when necessary

- Cleaning and lubricating caliper slide pins (for floating calipers)

- Checking for fluid leaks or damaged dust boots

- Ensuring the caliper moves freely and doesn’t stick

When troubleshooting brake issues, it’s important to consider both the master cylinder and calipers as potential sources of problems. Common symptoms and their possible causes include:

- Soft or spongy pedal: Air in the lines, worn master cylinder seals, or brake fluid leak

- Pulling to one side when braking: Stuck caliper or uneven pad wear

- Brake pedal sinks to the floor: Failed master cylinder or major leak in the system

- Squealing or grinding noises: Worn brake pads or damaged rotors

When working on brake systems, safety is paramount. Always use proper jack stands when lifting a vehicle, and be cautious of hot components. If you’re unsure about performing brake work, it’s best to consult a professional mechanic.

FAQs About Why Master Cylinder Brake Caliper

- How often should brake fluid be changed?

Most manufacturers recommend changing brake fluid every 2-3 years or 30,000 miles, but check your owner’s manual for specific guidance. - Can I replace just one brake caliper?

While possible, it’s generally recommended to replace calipers in pairs to ensure even braking performance on both sides of the axle. - What causes a brake caliper to stick?

Common causes include corrosion, damaged slide pins, or seized pistons, often due to lack of maintenance or exposure to road debris and moisture. - How do I know if my master cylinder is failing?

Signs include a sinking brake pedal, uneven braking, brake fluid leaks under the vehicle, or a warning light on the dashboard. - Is it normal for brake calipers to get hot?

Some heat is normal during operation, but excessive heat can indicate a stuck caliper or other brake system issues that should be inspected.