The master cylinder is a critical component of a vehicle’s braking system, serving as the heart that pumps brake fluid to activate the brakes. It converts the mechanical force applied to the brake pedal into hydraulic pressure, which is then distributed to the brake calipers or wheel cylinders at each wheel. This hydraulic pressure causes the brake pads or shoes to press against the rotors or drums, creating friction that slows and stops the vehicle. Without a properly functioning master cylinder, a car’s ability to brake effectively would be severely compromised, posing significant safety risks to drivers, passengers, and other road users.

The importance of the master cylinder in modern vehicles cannot be overstated. It plays a crucial role in ensuring consistent and reliable braking performance across various driving conditions. From sudden stops in emergency situations to gradual deceleration in everyday driving, the master cylinder’s ability to precisely control brake fluid pressure is essential for safe vehicle operation. Additionally, the master cylinder’s design incorporates safety features such as dual-circuit systems, which provide redundancy in case one circuit fails, further highlighting its critical role in vehicle safety.

| Master Cylinder Component | Function |

|---|---|

| Reservoir | Stores brake fluid |

| Pistons | Generate hydraulic pressure |

| Seals | Prevent fluid leakage |

| Ports | Connect to brake lines |

How Master Cylinder Brakes Work

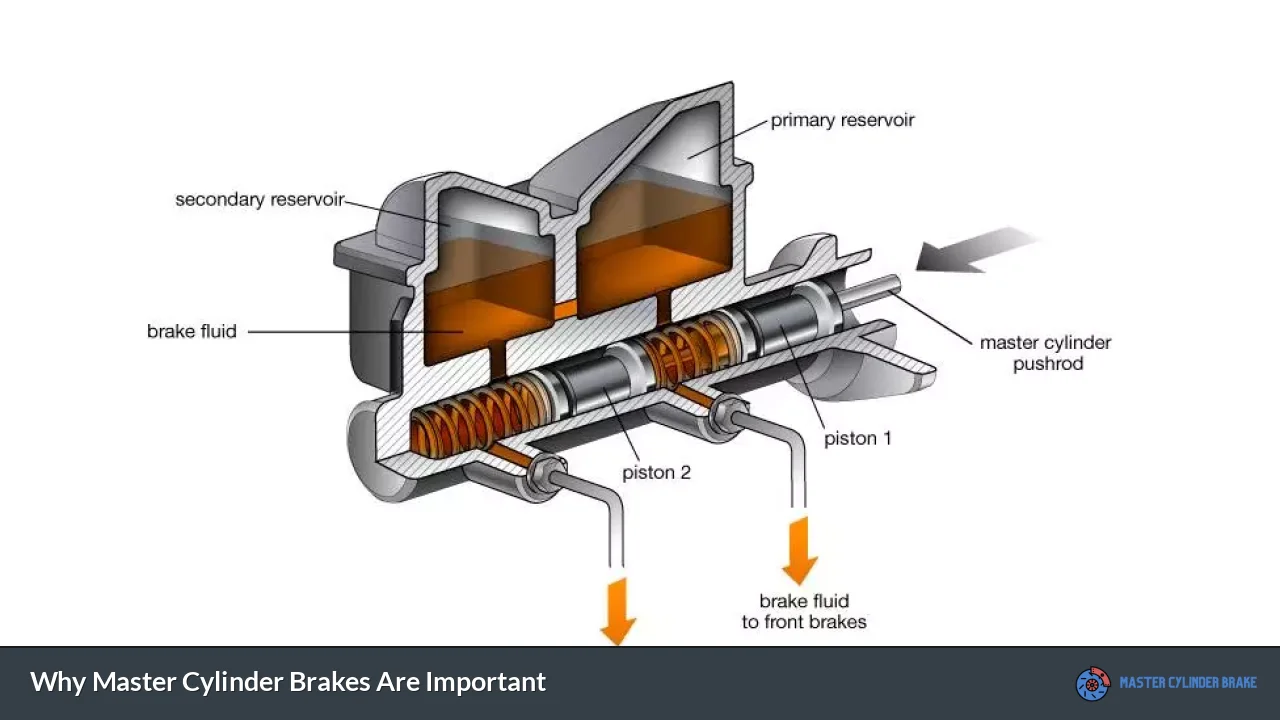

The operation of master cylinder brakes relies on the principles of hydraulics to amplify the force applied by the driver’s foot on the brake pedal. When the brake pedal is pressed, it pushes a rod connected to the primary piston inside the master cylinder. This piston moves forward, displacing brake fluid and creating pressure within the system. In modern vehicles, a tandem master cylinder design is used, which incorporates two pistons in series, each controlling a separate hydraulic circuit for added safety.

As the primary piston moves, it pushes brake fluid through the brake lines to the wheel cylinders or calipers. The pressure generated is proportional to the force applied to the brake pedal, allowing for precise control of braking force. This hydraulic pressure causes the brake pads to clamp down on the rotors in disc brake systems or pushes the brake shoes against the drums in drum brake systems. The result is a significant increase in friction between the brake components and the rotating parts of the wheel, effectively slowing or stopping the vehicle.

One of the key advantages of the master cylinder brake system is its ability to multiply the force applied by the driver. This hydraulic multiplication allows for effective braking with relatively little effort from the driver. The system also ensures that brake pressure is distributed evenly to all wheels, promoting stable and controlled deceleration. In the event of a failure in one hydraulic circuit, the dual-circuit design of modern master cylinders ensures that braking capability is maintained on at least two wheels, providing a crucial safety backup.

Types of Master Cylinders

There are several types of master cylinders used in modern vehicles, each designed to meet specific braking requirements and vehicle configurations. The most common types include:

- Single-circuit master cylinders: These older designs use a single hydraulic circuit to control all brakes. While simpler, they are less common in modern vehicles due to safety concerns.

- Dual-circuit master cylinders: The most common type in modern cars, featuring two separate hydraulic circuits for redundancy and improved safety.

- Tandem master cylinders: A specific design of dual-circuit systems where two pistons are arranged in series within a single bore.

- Portless master cylinders: Used in some high-performance applications, these eliminate the need for residual pressure valves by maintaining a small amount of pressure in the brake lines.

The choice of master cylinder type depends on factors such as vehicle weight, brake system design (disc or drum), and performance requirements. Dual-circuit systems have become the standard in automotive design due to their superior safety characteristics. In these systems, typically one circuit controls the front brakes and half of the rear brakes, while the other circuit controls the other half of the rear brakes and the remaining front brake. This configuration ensures that even if one circuit fails completely, the vehicle retains some braking capability.

Advantages of Dual-Circuit Master Cylinders

Dual-circuit master cylinders offer several significant advantages over single-circuit designs:

- Enhanced safety: By providing redundancy, they significantly reduce the risk of total brake failure.

- Improved braking balance: They allow for better distribution of braking force between front and rear wheels.

- Compliance with regulations: Most modern vehicle safety standards require dual-circuit braking systems.

- Easier maintenance: Issues in one circuit can often be isolated and repaired without affecting the entire system.

These advantages have made dual-circuit master cylinders an essential component in modern vehicle safety systems, contributing to the overall reduction in road accidents and fatalities over the years.

Maintenance and Care of Master Cylinder Brakes

Proper maintenance of the master cylinder is crucial for ensuring the longevity and reliability of a vehicle’s braking system. Regular inspections and timely repairs can prevent minor issues from escalating into major safety hazards. Here are some key aspects of master cylinder maintenance:

- Fluid level checks: Regularly inspect the brake fluid level in the reservoir. Low fluid levels can indicate leaks or worn brake pads.

- Fluid quality: Brake fluid should be clear and free from contaminants. Discolored or dirty fluid should be replaced.

- Seal integrity: Check for signs of fluid leakage around the master cylinder, which could indicate worn seals.

- Pedal feel: Pay attention to changes in brake pedal feel, such as sponginess or excessive travel, which could signal master cylinder issues.

- Periodic replacement: Some manufacturers recommend replacing the master cylinder at specific intervals as preventive maintenance.

It’s important to note that brake system maintenance often requires specialized knowledge and tools. Many tasks related to the master cylinder, such as bleeding the brake system or replacing the unit, are best left to qualified mechanics. However, vehicle owners can contribute to the longevity of their master cylinder by being attentive to changes in braking performance and addressing issues promptly.

Common Issues and Troubleshooting

Despite their robust design, master cylinders can develop problems over time. Recognizing the signs of a failing master cylinder is crucial for maintaining vehicle safety. Some common issues include:

- Brake fluid leaks: Visible fluid beneath the vehicle or a consistently low fluid level in the reservoir.

- Spongy brake pedal: Air in the brake lines or a failing master cylinder can cause a soft or spongy pedal feel.

- Brake warning light: Illumination of the brake warning light on the dashboard can indicate low fluid levels or other brake system issues.

- Contaminated brake fluid: Moisture or debris in the brake fluid can lead to corrosion and reduced braking efficiency.

- Uneven braking: If one circuit of a dual-circuit system fails, it may result in uneven braking performance.

When troubleshooting master cylinder issues, it’s important to approach the problem systematically. Start by checking the brake fluid level and quality, then inspect for visible leaks. If these basic checks don’t reveal the issue, further diagnostics may be necessary. Professional inspection is recommended for complex brake system problems to ensure accurate diagnosis and proper repair.

FAQs About Master Cylinder Brakes

- How often should brake fluid be changed?

Most manufacturers recommend changing brake fluid every 2 to 3 years or 30,000 miles, whichever comes first. - Can I drive with a failing master cylinder?

It’s not safe to drive with a failing master cylinder as it can lead to complete brake failure. - What causes a master cylinder to fail?

Common causes include wear and tear, contaminated brake fluid, and internal seal failure. - How long does a master cylinder typically last?

A well-maintained master cylinder can last 60,000 to 100,000 miles or more, but lifespan varies based on driving conditions and maintenance. - Can I replace a master cylinder myself?

While possible, it’s recommended to have a professional replace the master cylinder due to the complexity of bleeding the brake system.