Master cylinder brakes are a critical component of a vehicle’s braking system, but they can develop issues that make them problematic or even dangerous. While master cylinders are generally reliable, certain factors can lead to their failure or reduced performance. Understanding why master cylinder brakes can be bad is crucial for maintaining vehicle safety and performance.

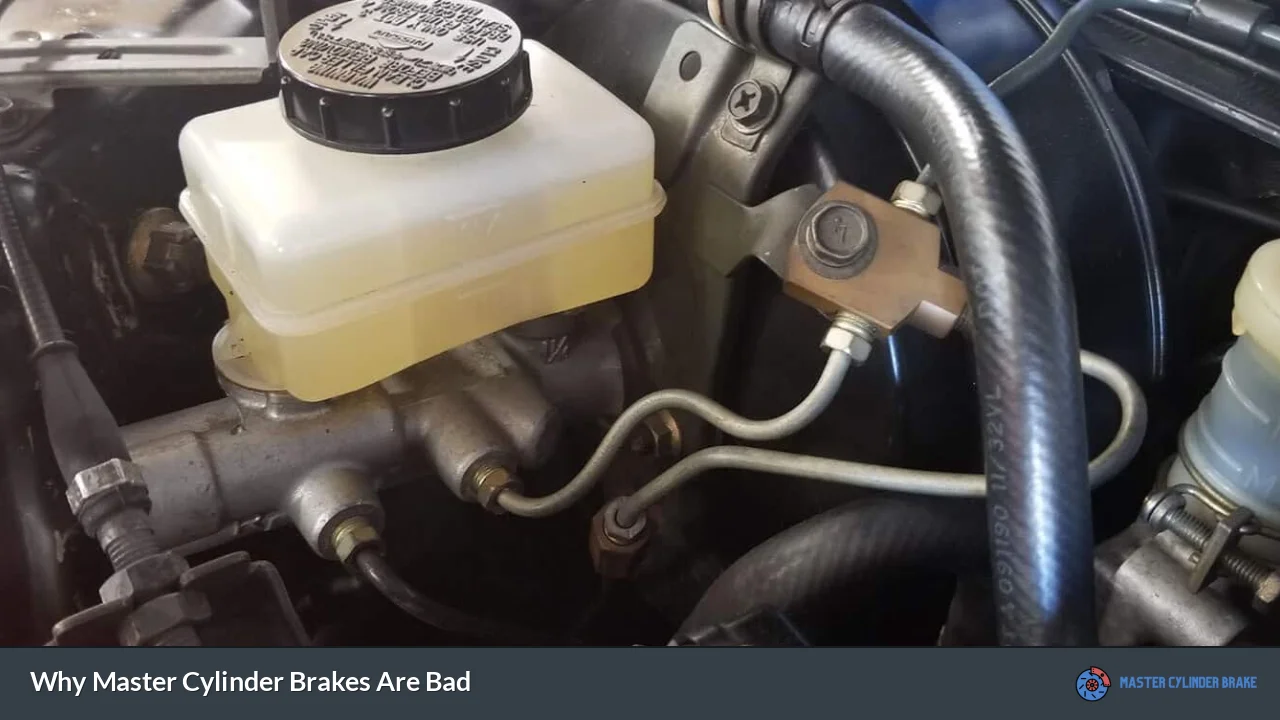

Master cylinder brakes convert the mechanical force applied to the brake pedal into hydraulic pressure, which then activates the brakes at each wheel. When functioning properly, this system provides consistent and reliable braking. However, various issues can arise that compromise the master cylinder’s effectiveness, potentially leading to brake failure or reduced braking power.

| Common Master Cylinder Issues | Potential Consequences |

|---|---|

| Fluid leaks | Loss of brake pressure |

| Internal seal failure | Inconsistent braking |

| Contaminated brake fluid | Reduced brake performance |

| Worn components | Increased stopping distance |

Fluid Leaks and Pressure Loss

One of the primary reasons why master cylinder brakes can be bad is the potential for fluid leaks. The master cylinder contains brake fluid under high pressure, and any leak in the system can lead to a loss of hydraulic pressure. This loss of pressure directly affects the braking force transmitted to the wheels, resulting in reduced braking efficiency or complete brake failure.

Leaks can occur due to various factors, including:

- Worn or damaged seals

- Corroded cylinder walls

- Cracked reservoir

- Loose fittings or connections

When a leak develops, it often starts small and may not be immediately noticeable. However, even a minor leak can worsen over time, leading to a gradual decrease in braking performance. In severe cases, a significant leak can cause the brake pedal to sink to the floor, leaving the driver with little to no braking ability.

Regular inspection of the master cylinder and surrounding components is crucial for detecting leaks early. Signs of a leak may include:

- Visible fluid puddles under the vehicle

- Low brake fluid levels in the reservoir

- Soft or spongy brake pedal feel

- Decreased braking performance

Addressing leaks promptly is essential to maintain the integrity of the braking system and ensure vehicle safety.

Internal Seal Failure and Contamination

Another reason why master cylinder brakes can be bad is the potential for internal seal failure. The master cylinder contains several seals that prevent brake fluid from bypassing the pistons and maintain proper pressure. Over time, these seals can deteriorate, leading to internal leaks and reduced braking efficiency.

Seal failure can be caused by:

- Normal wear and tear

- Exposure to extreme temperatures

- Contaminated brake fluid

- Manufacturing defects

When internal seals fail, brake fluid can bypass the pistons, resulting in a loss of hydraulic pressure. This can cause the brake pedal to feel soft or spongy and may require multiple pumps to build up sufficient pressure for braking.

Contamination of the brake fluid is another significant issue that can affect master cylinder performance. Brake fluid is hygroscopic, meaning it absorbs moisture from the air. Over time, this absorbed moisture can lead to corrosion of internal components and degradation of the fluid’s boiling point.

Contaminated brake fluid can cause:

- Reduced braking efficiency

- Premature wear of internal components

- Formation of sludge or deposits in the system

- Increased risk of brake fade during heavy use

Regular brake fluid changes and system flushes are essential to prevent contamination and maintain optimal master cylinder performance.

Wear and Component Failure

Master cylinder brakes can also become problematic due to general wear and component failure. Like any mechanical system, the master cylinder and its associated parts are subject to wear over time. This wear can lead to reduced performance and potentially dangerous situations if left unaddressed.

Common wear-related issues include:

- Piston wear or scoring

- Spring fatigue

- Reservoir cap deterioration

- Pushrod misalignment

As components wear, they may not function as efficiently, leading to increased pedal travel, reduced braking force, or inconsistent brake application. In some cases, worn components can cause the master cylinder to fail suddenly, resulting in a complete loss of braking ability.

Regular maintenance and inspection are crucial for identifying wear before it leads to failure. Signs of wear may include:

- Increased pedal travel

- Inconsistent brake pedal feel

- Unusual noises when applying the brakes

- Visible damage or corrosion on external components

Addressing wear-related issues promptly can help prevent more serious problems and ensure continued safe operation of the vehicle.

Design Limitations and Compatibility Issues

While not inherently bad, master cylinder brakes can sometimes be problematic due to design limitations or compatibility issues. In some cases, the master cylinder may not be properly matched to the vehicle’s braking system, leading to suboptimal performance or increased wear.

Factors that can contribute to compatibility issues include:

- Incorrect bore size

- Mismatch between master cylinder and brake booster

- Improper pedal ratio

- Inadequate fluid volume capacity

When a master cylinder is not properly matched to the vehicle’s braking system, it can result in:

- Hard or overly sensitive brake pedal feel

- Insufficient braking force

- Premature wear of brake components

- Increased risk of brake fade during heavy use

Ensuring proper compatibility between the master cylinder and other braking system components is crucial for optimal performance and safety. When replacing or upgrading brake components, it’s essential to consider the entire system to avoid potential issues.

Maintenance and Repair Challenges

Another aspect that can make master cylinder brakes problematic is the difficulty of maintenance and repair. While master cylinders are generally reliable, when issues do arise, they can be challenging and expensive to address.

Challenges in maintaining and repairing master cylinders include:

- Limited access in some vehicle designs

- Specialized tools required for certain repairs

- Potential for introducing air into the system during service

- High cost of replacement parts

These challenges can lead to delayed maintenance or improper repairs, potentially compromising the safety and performance of the braking system. Additionally, the complexity of modern braking systems, including ABS and stability control, can make diagnosing and repairing master cylinder issues more difficult for the average DIY mechanic.

Regular professional inspections and maintenance can help identify and address potential issues before they become major problems. However, the cost and complexity of repairs can be a significant drawback for some vehicle owners.

FAQs About Why Master Cylinder Brakes Are Bad

- How often should a master cylinder be replaced?

Master cylinders typically last 60,000-100,000 miles, but regular inspections are crucial for early problem detection. - Can a bad master cylinder cause uneven braking?

Yes, a faulty master cylinder can lead to uneven brake pressure distribution, causing inconsistent or pull-to-one-side braking. - What are the signs of a failing master cylinder?

Common signs include a sinking brake pedal, fluid leaks, warning lights, and decreased braking performance. - Is it safe to drive with a bad master cylinder?

No, driving with a faulty master cylinder is extremely dangerous as it can lead to complete brake failure. - Can extreme temperatures affect master cylinder performance?

Yes, extreme heat or cold can cause brake fluid to expand or contract, potentially affecting master cylinder operation.